The Dawn of Autonomous Agency in Global Logistics The global supply chain is currently standing at a pivotal crossroads, driven by the rapid emergence of agentic artificial intelligence which possesses the ability to reason, adapt, and execute complex workflows independently. Unlike traditional

Global supply chain networks have reached a critical inflection point where the sheer velocity of market disruptions has consistently outpaced the ability of human operators to react using traditional methods. For decades, the industry relied on a "break-fix" mentality, treating logistical

Rohit Laila brings decades of deep-seated experience to the table, having navigated the complex intersection of global logistics, supply chain management, and cutting-edge delivery technology. His career has been defined by a commitment to innovation, helping organizations transition from legacy

The modern global supply chain is no longer a linear sequence of events but a complex, high-velocity network where a single second of latency can ripple into millions of dollars in lost revenue. Traditional warehouse management has historically functioned as a digital island, often detached from

Rohit Laila brings over two decades of deep-rooted expertise to the global logistics and supply chain landscape, having navigated the intricate evolution of delivery networks from traditional manual operations to the cutting-edge automated hubs of today. His career is defined by a relentless

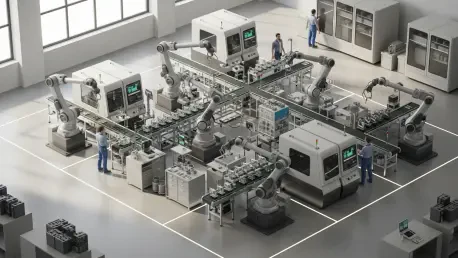

The long-standing boundary between high-speed mechanical power and human safety has finally been breached by a generation of machines that no longer require steel cages to operate. For decades, the industrial floor was a binary environment: you either had the raw speed of a caged industrial arm or

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66