The deceptively simple shoebox, a ubiquitous container in the world of fashion logistics, has long represented a formidable challenge for warehouse automation systems that excel at handling standardized, rigid packages. For years, the two-piece, unsealed design has been the bane of robotic picking arms, with flimsy lids that separate easily, spilling contents and causing costly disruptions on the fulfillment line. This single, seemingly minor obstacle has forced many companies to rely on manual labor for a task that cries out for automation, highlighting a critical gap between robotic capability and real-world commercial needs. A breakthrough in this area would not only streamline a key segment of the supply chain but also signal a new era of dexterity and intelligence for physical AI. Now, a specialized robotics company is tackling this problem head-on, backed by significant new investment and a platform designed to master the delicate art of handling even the most troublesome inventory. This development promises to redefine the boundaries of what is considered “pickable” in a modern warehouse.

A New Wave of Funding and Innovation

Poland-based warehouse robotics firm Nomagic, which specializes in applying physical AI to complex logistics operations, has fortified its market position with a substantial new round of funding aimed at fueling its next phase of growth. The company announced a $10 million Series B extension, a move spearheaded by lead investor Cogito Capital Partners, which brings its cumulative funding to an impressive total exceeding $84 million. This infusion of capital is strategically allocated to accelerate commercial expansion and deepen the company’s technological advantage. A primary objective is the continued scaling of its operations within the United States, an initiative that began in 2025 and is set to intensify. Furthermore, a significant portion of the funds will be directed toward advancing the development of its sophisticated visual language action (VLA) models. These models are crucial for enhancing the robots’ ability to understand and interact with their environment in a more human-like, intuitive manner, paving the way for more autonomous and adaptable warehouse solutions.

The Mechanics of Physical AI

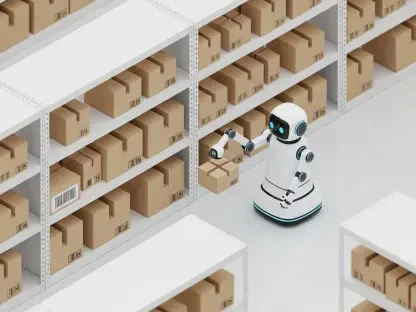

In a major product reveal, Nomagic has introduced the Shoebox Picker, a highly advanced robotic system engineered specifically to resolve one of the most persistent bottlenecks in fashion and footwear logistics. The system’s design integrates an AI-driven perception and control platform with a uniquely intelligent end-of-arm gripper, allowing it to perform with a level of precision previously unattainable in automated systems. At the heart of its operation is a sophisticated technology that analyzes the distinct characteristics of each individual shoebox. It assesses variables such as size, weight, lid type, and its precise orientation within a bin or on a shelf. Based on this real-time analysis, the system’s AI calculates and executes the ideal picking motion required to securely handle the item. This capability allows it to manage what has often been deemed unpickable: two-piece, unsealed shoeboxes. The robot can lift and move these items without requiring any tape or external securing, effectively preventing lids from separating and contents from spilling during the handling process.

The Shoebox Picker demonstrates several unique capabilities that set it apart in the crowded field of warehouse automation, exemplifying the practical application of what the company’s CEO, Kacper Nowicki, terms “Physical AI.” This concept refers to the embodiment of artificial intelligence within a physical system designed to interact with and solve tangible, real-world problems. The robot’s versatility is a key feature; it can adeptly manage a diverse mix of shoebox designs and materials, from glossy cardboard to textured finishes, and can pick boxes from both vertical and horizontal orientations with equal proficiency. This adaptability is critical in dynamic warehouse environments where product variety is the norm. The investor, Cogito Capital Partners, has reinforced this view, highlighting that Nomagic’s approach directly addresses one of the most urgent transformation needs within the logistics industry. By solving such a nuanced challenge, the company is not just offering a new product but is also positioning itself to redefine global standards for intelligent automation in a rapidly evolving sector.

A New Benchmark in Dexterity

The successful deployment of a system capable of mastering the shoebox problem represented a significant milestone for the broader field of physical AI. It was a clear demonstration that robotic automation had evolved beyond handling simple, uniform objects to managing items with complex, delicate, and unpredictable characteristics. This achievement challenged long-held assumptions about the limitations of robotic dexterity and perception. The ability to analyze and adapt to each unique shoebox in real time showcased a new level of machine intelligence that moved closer to the nuanced judgment of a human worker. Consequently, this breakthrough did more than just solve a specific logistics issue; it established a new benchmark for what was considered possible, signaling that other “unpickable” items across different industries might soon be within the grasp of automated systems. The conversation shifted from the constraints of automation to the new frontiers it could now explore.