The journey of a single online order, from a click to a doorstep, culminates in a complex and rapid-fire ballet of vehicles and personnel at the warehouse loading bay. In the fast-paced world of modern logistics, this critical junction point has become a high-stakes environment where operational success and human safety are inextricably linked. As fulfillment demands accelerate and vehicle fleets diversify, industry leaders are increasingly focusing their attention on this often-overlooked area, recognizing that a safe loading dock is the bedrock of an efficient, compliant, and resilient supply chain. This roundup synthesizes insights and case studies from across the sector, exploring the innovative strategies and technologies that are setting new benchmarks for safety and performance.

The New Nexus of Warehouse Operations: Why Loading Docks Demand Our Attention

The relentless pace of e-commerce and just-in-time inventory models has transformed the once-predictable loading dock into a hub of constant activity. This high-velocity environment amplifies the pressure on every aspect of warehouse operations, demanding unprecedented speed and precision. The sheer volume and variety of traffic, from last-mile delivery vans to massive double-deck trailers, introduce a level of complexity that older facilities were never designed to handle, making the loading bay a primary area of operational risk.

Consequently, a direct and critical link has emerged between loading bay safety, overall operational efficiency, and stringent regulatory compliance. A single incident can trigger a cascade of negative consequences, including serious injuries, costly downtime, and potential legal liabilities. Forward-thinking organizations now understand that safety is not a separate consideration but a core component of productivity. A well-designed, secure loading bay facilitates smoother turnarounds, reduces product damage, and ensures a stable, reliable workflow. This new understanding is driving an industry-wide exploration of how advanced equipment, strategic facility design, and collaborative standard-setting are combining to redefine the future of warehouse safety.

Forging a Safer Future: Innovations and Strategies in Loading Bay Management

Beyond the Standard Dock: Adapting to a Diverse and Demanding Fleet

The modern logistics fleet is no longer uniform. Today’s loading docks must safely and efficiently service everything from small electric vans completing urban deliveries to towering double-deck trailers designed for maximum hauling capacity. This diversity presents a significant engineering challenge, as a standard-height dock is often incompatible with vehicles at either end of the size spectrum, creating dangerous gaps and inclines.

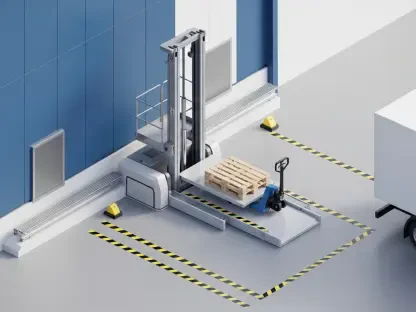

Industry analysis points toward versatile, level-access loading solutions as a key response. A compelling case study comes from the retailer Next, which implemented a Vehicle-to-Ground (V2G) lift installation. This technology provides a flexible platform that can be adjusted to meet the precise height of any vehicle, ensuring a flat and stable surface for loading and unloading. While some managers debate the initial investment in such highly adaptable systems against the perceived cost of potential underutilization, the consensus is shifting. The operational and safety risks associated with an inflexible dock are increasingly seen as a far greater long-term expense than the cost of future-proofing the facility.

Retrofitting for Resilience: Transforming Legacy Docks into Modern Assets

Many existing warehouses operate with legacy infrastructure that poses significant safety and efficiency challenges. A prominent trend involves converting outdated internal systems, such as in-floor scissor lifts, to external loading bay pods. These self-contained units are built onto the exterior of the building, providing a modern, integrated system of dock leveler, shelter, and door.

A supermarket chain’s recent transition offers a powerful example of this strategy’s benefits. By replacing hazardous internal scissor lifts, the company eliminated dangerous open pits from the warehouse floor, drastically reducing the risk of falls and equipment damage. Moreover, the new external pods were designed to accommodate double-deck trailers, a capability the old system lacked. This upgrade not only fortified the facility’s safety profile but also unlocked new efficiencies and increased throughput. While any major facility upgrade involves operational risk during the transition period, the long-term competitive advantage gained through enhanced safety and capacity makes a compelling business case for modernization.

The Human Element: Integrating Protocols and Training with Technology

Even the most sophisticated loading bay technology is incomplete without a corresponding investment in human-centric safety measures. Advanced equipment can mitigate many risks, but it cannot eliminate the potential for human error. Industry best practices emphasize a holistic approach where technology and robust operational protocols work in tandem to create a truly safe environment.

This principle is clearly illustrated by a project for a manufacturing specialist that involved installing a new loading ramp. The physical equipment was only one part of the solution. The successful implementation hinged on a comprehensive safety package that included mandatory operator training, the strict use of wheel chocks to prevent vehicle creep, and the installation of sturdy handrails to protect personnel. This approach challenges the common but dangerous assumption that technology can serve as a complete substitute for procedural discipline. In high-risk environments like the loading bay, well-trained and vigilant personnel remain the most critical safety asset.

Codifying Caution: How Industry Standards Shape Safer Infrastructure

The push for safer loading bays is not just happening at the individual company level; it is also being driven by collaborative industry-wide efforts. Organizations like the Association of Loading and Docking Equipment Manufacturers (ALEM) play a crucial role in elevating safety standards across the board by fostering a culture of continuous improvement and shared responsibility.

By engaging with government bodies and contributing to the development and revision of key technical standards, such as EN1398 for dock levelers, these associations help codify best practices into enforceable regulations. This work ensures that new equipment is designed and manufactured to meet a high, consistent safety baseline, protecting workers and providing clarity for businesses. As automation, robotics, and new vehicle technologies continue to reshape logistics, the role of these standard-setting bodies will become even more critical in navigating emerging risks and ensuring that safety innovation keeps pace with operational evolution.

Your Blueprint for a Secure and Efficient Loading Environment

The collective insights from the logistics sector point toward a clear blueprint for creating a secure and highly efficient loading environment. The core principles are threefold: prioritizing adaptable equipment capable of handling a diverse fleet, strategically redesigning legacy spaces to eliminate inherent hazards, and embedding robust safety protocols that integrate human action with technological safeguards. Together, these elements form a comprehensive strategy for mitigating risk and maximizing operational performance.

For facility managers ready to take action, a proven three-step plan offers a structured path forward. The process begins with a comprehensive risk audit of the current loading bay to identify specific vulnerabilities. The next step is to invest in tailored, compliant technology that directly addresses those identified risks. Finally, this investment must be supported by the implementation of continuous and rigorous operator training programs. Simple yet effective solutions, such as durable, low-maintenance curtain dock shelters, are often highlighted for high-turnover operations, providing a reliable seal against the elements while requiring minimal upkeep.

The Unyielding Connection Between Dock Safety and Logistics Success

The evidence gathered from across the supply chain led to an undeniable conclusion: investment in high-quality, compliant loading bay technology was no longer an optional expense but a fundamental pillar of modern logistics. As market pressures and fulfillment speeds intensified, the loading bay solidified its position as a critical point of operational leverage, where success or failure was often decided. Leaders who viewed the modernization of their docks not as a cost but as a core investment in business resilience and operational excellence consistently outperformed their competitors, building a foundation for sustainable growth and a safer working environment.