Recent data from the Association for Advancing Automation (A3) reveals that the North American robotics market not only grew in 2025 but underwent a fundamental transformation that is reshaping the industrial landscape. With companies ordering 36,766 robots throughout the year, marking a 6.6% increase over 2024, the sector demonstrated robust health. This surge in volume was matched by a significant 10.1% rise in total order value, which climbed to an impressive $2.25 billion. These figures, however, only tell part of the story. Beneath the surface of this expansion lies a pivotal shift in where and how automation is being deployed. The traditional dominance of the automotive sector has given way to a more diversified and dynamic market, driven by a growing confidence among businesses that see automation not merely as a tool for efficiency but as a strategic imperative for resilience, growth, and competitiveness in an ever-evolving global economy. This diversification points to a future where robotics becomes ubiquitous across nearly every commercial sector.

Diversification Beyond the Assembly Line

The most significant trend to emerge from the 2025 data is the remarkable diversification of the robotics market, with non-automotive sectors collectively becoming the primary engine of growth. For the first time, “general industries”—a broad category encompassing food and consumer goods, semiconductors, electronics, and life sciences—ordered more robots than their automotive counterparts. This milestone signals a crucial turning point, indicating that automation has broken free from its traditional stronghold on the vehicle assembly line. This expansion is being fueled by a confluence of pressing economic factors. Businesses across these varied sectors are increasingly turning to robotics as a long-term, strategic solution to persistent labor shortages. Furthermore, as companies accelerate reshoring initiatives to build more resilient domestic supply chains, automation provides the means to enhance productivity and maintain cost-competitiveness on a global scale, solidifying its role as an indispensable component of modern industrial strategy.

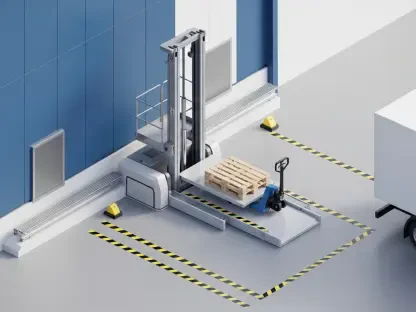

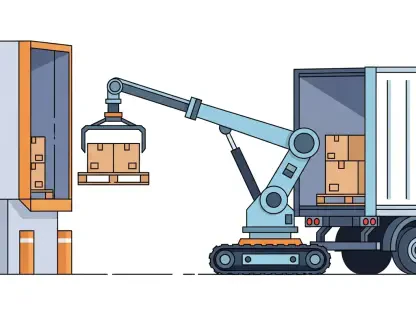

The growing adoption of robotics in non-automotive fields reflects a renewed and broadened confidence in the technology’s capabilities and return on investment. While manufacturing remains a core application, the deployment of robots in areas like logistics, warehousing, and even intricate life sciences processes highlights their increasing versatility. This trend underscores a deeper understanding among business leaders that automation is no longer a niche solution for large-scale, repetitive tasks but a flexible tool adaptable to a wide array of operational challenges. The sustained investment from industries as diverse as food processing and consumer electronics demonstrates a collective belief that integrating robotics is essential for future-proofing operations. This confidence is not just about replacing manual labor; it’s about augmenting human capabilities, improving product quality, increasing operational speed, and ultimately, building more agile and resilient enterprises capable of navigating future economic uncertainties and market demands.

A Glimmer of Hope for Automotive and the Rise of Cobots

While the spotlight in 2025 shifted to general industries, the automotive sector showed signs of a noteworthy recovery that could foreshadow future stability. Although overall orders for automotive components remained below the levels seen in 2024, a significant positive development was observed in orders from automotive original equipment manufacturers (OEMs). This rebound, which gained considerable momentum in the second half of the year, is widely interpreted by analysts as a crucial leading indicator. The increased investment from major vehicle manufacturers suggests a potential stabilization and a return to growth for the broader automotive supply chain as it enters the current year. This resurgence, driven by the industry’s own push toward electrification and advanced manufacturing techniques, signals that while its market share may have changed, the automotive sector remains a formidable and influential force in the robotics landscape, with its recovery poised to contribute to the market’s overall strength.

Further evidence of the market’s dynamic evolution was the meteoric rise of collaborative robots, or cobots, which have rapidly become a cornerstone of modern automation strategies. Throughout 2025, cobots represented a substantial 19.6% of all robotic units ordered, totaling 7,212 units. In terms of revenue, they accounted for 10.7% of the market with a value of $241 million. This impressive annual performance was punctuated by an exceptionally strong fourth quarter, where cobot orders reached their highest-ever quarterly volume, indicating an accelerating adoption curve. The increasing preference for cobots is tied to their inherent flexibility, ease of integration, and ability to work safely alongside human employees. Unlike traditional industrial robots that require extensive safety caging and complex programming, cobots offer a more accessible entry point into automation for small and medium-sized enterprises, driving the technology’s expansion into new applications and industries that were previously underserved.

The New Horizon for Automation

The market dynamics of 2025 solidified a new trajectory for the robotics industry, marking a departure from its historical patterns. The year was defined by a profound diversification that saw non-automotive sectors emerge as the new leaders in automation adoption, a trend driven by the urgent need to address labor gaps and enhance domestic production capabilities. This broadening of the user base confirmed that robotics had evolved into a versatile and indispensable tool for a wide spectrum of industries. Simultaneously, the automotive sector, while no longer the sole dominant force, demonstrated a resilient recovery in its core manufacturing operations, suggesting a period of stabilization ahead. The most telling development, however, was the mainstreaming of collaborative robots, which shattered previous records and became integral to modern automation strategies. These intersecting trends painted a clear picture of a more mature, accessible, and diversified robotics market, one poised for sustained and widespread growth.