Atlanta-based robotics innovator Slip Robotics has officially launched SlipLift, an advanced autonomous mobile robot platform engineered to dramatically expand the scope of automated freight handling across the supply chain. This new system promises to bring the speed and safety of automation to a much wider array of industries, moving beyond niche applications to address the universal challenges of loading dock inefficiency. SlipLift’s introduction signals a significant step toward making five-minute trailer turnarounds not just a possibility, but a standard operational benchmark.

The Loading Dock Dilemma and a Five Minute Turnaround

For decades, the loading dock has remained a stubborn bottleneck in an otherwise increasingly automated supply chain, a place where manual labor, safety risks, and unpredictable delays converge. The process of loading and unloading trailers is physically demanding and time-consuming, often creating a ripple effect of inefficiency that impacts everything from driver detention times to warehouse inventory flow. This persistent challenge has driven a search for solutions that can deliver both speed and consistency without requiring massive capital investment in facility redesign.

Slip Robotics aims to solve this dilemma by establishing a new standard: the five-minute turnaround. The company’s technology is designed to transform the chaotic, hours-long process of loading a trailer into a swift, predictable, and repeatable task. By automating the most hazardous and strenuous part of the job—moving heavy freight inside the confined space of a trailer—the system not only accelerates operations but also significantly enhances worker safety. This level of efficiency removes a critical variable from logistics planning, allowing for more reliable scheduling and asset utilization.

Beyond Repetitive Routes: Toward Flexible Automation

Early forays into dock automation often centered on “milk runs”—short, high-frequency, and highly predictable routes where the same type of freight moves between the same two points repeatedly. While effective for these specific use cases, such solutions lacked the flexibility to address the diverse and dynamic nature of modern logistics. The industry’s greater need is for an automation platform that can adapt to varying freight types, trailer sizes, and operational workflows, from regional distribution centers to the final stages of last-mile delivery.

The market has been calling for a system that can handle the variability of day-to-day logistics without requiring dedicated infrastructure at every dock door. This means accommodating everything from pallets of consumer packaged goods to dense automotive parts. The key is to provide a universal tool that integrates seamlessly into existing operations, rather than forcing businesses to overhaul their processes to fit the technology. SlipLift was developed as a direct answer to this demand for a more versatile and scalable automation solution.

Introducing SlipLift: A Decoupled Approach to Operations

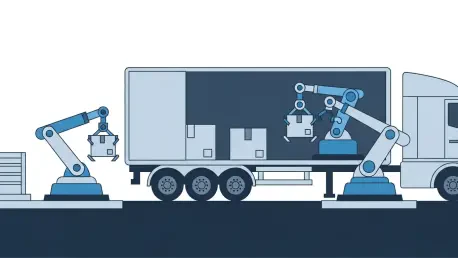

The fundamental innovation behind SlipLift is its decoupled architecture, which separates the autonomous robot from the payload it transports. Unlike systems where a robot is tied to a single load for the duration of its journey, SlipLift robots can service multiple loads and dock doors in quick succession. This design philosophy dramatically improves asset utilization, allowing a small fleet of robots to manage the workflow of a much larger facility, thereby changing the economic model for dock automation.

The SlipLift ecosystem consists of three core components working in harmony. At the center is the SlipLift robot, an autonomous mobile platform built on the company’s proven SlipBot technology. This robot interacts with SlipCarriers, which are essentially large, mobile platforms onto which freight is pre-staged on the dock. The entire operation is overseen by a human operator, who uses a simple handheld controller from a safe distance outside the trailer to guide the process, ensuring the robot handles the heavy lifting while the human provides high-level supervision. This workflow redefines efficiency by allowing dock workers to prepare multiple loads simultaneously while the robot executes the transport and placement tasks inside the trailer.

A Direct Response to Overwhelming Industry Demand

According to CEO Chris Smith, the development of SlipLift was a direct response to feedback from clients who were impressed by the speed of the original SlipBot system but required a solution that could be applied more broadly across their networks. Customers sought to extend the benefits of predictable, rapid loading cycles to heavier freight classes and less frequent shipping routes. The consensus was clear: the industry needed an adaptable platform that could scale efficiently across diverse operational environments.

SlipLift was engineered to meet these specific demands. It supports payloads up to 20,000 pounds, a capability that opens the door to automating freight handling in demanding sectors such as food and beverage, paper products, packaging, and heavy automotive components. By listening to the market and focusing on scalability, Slip Robotics designed a system that addresses the practical, real-world challenges faced by logistics managers, moving beyond a niche solution to offer a more universal application of its core technology.

From High Frequency Routes to a Universal Solution

With its expanded capabilities, SlipLift is positioned to unlock new levels of efficiency across the entire supply chain, far beyond its origins in high-frequency shuttle runs. For regional distribution and last-mile logistics, where speed and accuracy are paramount, the ability to pre-stage loads on SlipCarriers transforms a traditionally chaotic process into a streamlined, predictable operation. This is particularly valuable in dynamic environments where a wide variety of goods must be loaded into different types of vehicles, from 53-foot trailers to smaller box trucks.

The system delivers key performance gains in speed, safety, and simplicity without necessitating expensive or disruptive infrastructure modifications. Facilities can deploy SlipLift without altering their docks, trailers, or IT systems, ensuring a rapid and frictionless integration. Furthermore, the stackable design of the SlipCarriers helps conserve valuable floor space on crowded docks when they are not in use. As initial deployments of SlipLift have begun, the technology has demonstrated its potential to make automated loading a practical and accessible solution for a much broader segment of the logistics industry.