The evolution of intelligent robotics has reached a critical bottleneck, where the purely visual perception that has driven progress for years is proving insufficient for interacting with the unstructured complexity of the real world. Robotic tactile sensing represents a significant advancement in robotics and artificial intelligence, offering the sense of touch that machines need to achieve true physical dexterity. This review will explore the evolution of the technology, its key transduction principles, performance metrics, and the impact it has had on various applications. The purpose of this review is to provide a thorough understanding of tactile sensing, its current capabilities, and its potential future development as a cornerstone of Physical AI.

An Introduction to the Sense of Touch in Robotics

Robotic tactile sensing introduces the fundamental ability for a machine to feel its environment. The core principle of the technology is the measurement of physical interaction, translating contact, force, pressure distribution, and texture into quantifiable data. This sensory input allows a robot to understand not only where an object is but also how it is being held, whether it is slipping, and what its surface properties are. It is the digital equivalent of the complex network of receptors in human skin.

This capability is critical for enabling robots to move beyond simple, repetitive automation to perform complex manipulation tasks. In environments where objects are not perfectly positioned or have variable shapes and weights, vision alone cannot provide the feedback necessary for a successful grasp. Tactile sensing contextualizes visual data, providing the ground truth that confirms contact and guides fine motor control. Its emergence as a key enabler is transforming robots into more adaptive and intelligent systems capable of nuanced interaction.

Core Technologies and Transduction Principles

Piezoresistive and Strain Gauge Sensors

Piezoresistive and strain gauge sensors are among the most established and robust technologies in tactile sensing. Their operation is based on a simple yet effective principle: the material’s electrical resistance changes when it is subjected to mechanical strain. These sensors are typically constructed from a flexible substrate embedded with a conductive material, such as doped silicon or a polymer composite. When a force is applied, the substrate deforms, altering the path for electrical current and producing a measurable change in resistance.

Due to their straightforward design and durable materials, these sensors are prized for their reliability in providing robust force feedback. While they can exhibit challenges like hysteresis—a lag in returning to their original state after a force is removed—their stability and direct correlation between force and resistance make them a go-to choice for industrial applications. They provide the clear, consistent force measurement needed for tasks requiring strength and precision over millions of cycles.

Capacitive and Piezoelectric Sensors

Capacitive sensors operate by detecting a change in capacitance when an external force is applied. A typical sensor consists of two conductive plates separated by a compressible dielectric material. As pressure is applied, the distance between the plates decreases, causing the capacitance to increase. This method is known for its high sensitivity to even light touch and its excellent response to both static and dynamic forces, making it ideal for delicate manipulation tasks.

In contrast, piezoelectric sensors generate a voltage in direct response to mechanical stress, a phenomenon known as the piezoelectric effect. These sensors excel at measuring dynamic events, such as impacts or vibrations, as they only produce a signal when the applied force is changing. This characteristic makes them particularly well-suited for applications like slip detection, where the high-frequency signals associated with an object beginning to move can be captured in real time.

Optical and Vision Based Tactile Sensing

A more modern approach to tactile sensing involves the use of embedded cameras and light to infer highly detailed contact information. Technologies like GelSight are at the forefront of this category, typically employing a block of clear, soft gel with a reflective membrane. When the gel makes contact with an object, it deforms, and an internal camera captures the distortion of a light pattern projected onto the membrane.

This vision-based method offers significant advantages, most notably its ability to capture high-resolution maps of force distribution, object texture, and surface geometry from a single sensor. The rich, image-like data stream is particularly valuable for training machine learning models, as it provides a wealth of information that can be used to teach a robot complex manipulation skills. The growing importance of this technology in research signals a shift toward more data-intensive methods for achieving robotic dexterity.

Bio Inspired and Soft Tactile Sensors

Drawing inspiration from the complexity of human skin, bio-inspired and soft tactile sensors are designed to be flexible, compliant, and multi-modal. These sensors are fabricated using soft, stretchable materials like elastomers and hydrogels, which allow them to conform to irregularly shaped objects and interact safely with their environment. This compliance minimizes the risk of damaging delicate items and provides a more stable, encompassing grasp.

The primary advantage of these soft systems is their ability to mimic the distributed sensing capabilities of biological skin. Researchers are developing sensors that can simultaneously detect pressure, temperature, and shear forces, providing a holistic understanding of a physical interaction. While still largely in the research phase, the development of these skin-like sensors is a crucial step toward creating robots that can interact with the world as safely and intuitively as humans do.

Emerging Trends and Innovations

The field of tactile sensing is currently defined by the deep integration of its data with advanced machine learning algorithms. High-frequency tactile information is proving to be an essential component for training robust Physical AI models through techniques like reinforcement learning and imitation learning, allowing robots to generalize skills across varied objects and scenarios. This trend moves beyond simple feedback control toward genuine learned behaviors.

Furthermore, innovation is pushing toward the development of multi-modal sensors that fuse touch with other sensory data, such as temperature or proximity, to provide a richer, more complete picture of an interaction. On the hardware front, a significant push is underway to create more durable, scalable, and cost-effective sensors. The goal is to move tactile technology out of the research lab and make it a standard, deployable component in industrial and commercial robotics.

Key Applications Across Industries

Advanced Manufacturing and Assembly

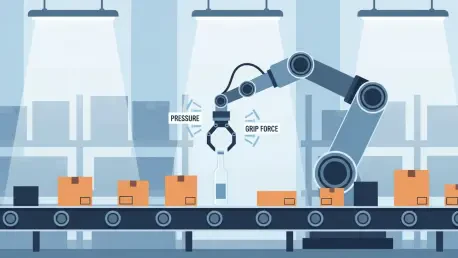

In advanced manufacturing, tactile sensing enables a level of precision and quality control that was previously unattainable with automation. Robots equipped with tactile grippers can perform precision gripping of delicate electronic components, ensuring that just enough force is applied without causing damage. These sensors also facilitate automated quality control by allowing a robot to feel for surface imperfections, gaps, or misalignments in assembled parts, increasing production efficiency and dramatically reducing errors.

This technology is particularly transformative in the assembly of complex products. For tasks that require inserting a part into a tight-fitting socket, tactile feedback allows the robot to feel for resistance and adjust its path accordingly—a process known as peg-in-hole insertion. This capability is crucial for automating the final assembly stages of electronics, automotive components, and aerospace systems, which often demand fine motor skills.

Healthcare Surgery and Prosthetics

The impact of tactile feedback is profound in the healthcare sector, especially in robotic surgery. When surgeons operate a robotic system, integrated tactile sensors can transmit the feeling of tissue tension and instrument contact back to the surgeon’s hands, restoring a degree of the haptic feedback lost in remote procedures. This improved instrument control can lead to more precise operations and better patient outcomes.

In the realm of prosthetics, tactile sensing is a game-changer for restoring a sense of touch to amputees. Advanced prosthetic limbs integrated with tactile sensors on the fingertips can provide users with feedback about pressure and texture, allowing them to hold fragile objects like an egg without breaking it or to identify objects by feel. Similarly, assistive robots in elder care or rehabilitation use touch to ensure safe and gentle human-robot interaction.

Logistics and Agriculture

Within the sprawling warehouses of e-commerce, tactile sensors grant robots the ability to reliably handle an ever-changing variety of items. Unlike traditional automation designed for uniform products, tactile-enabled robots can adjust their grip force for objects of different weights, textures, and fragilities, from a heavy book to a soft bag of chips. This adaptability is essential for automating order fulfillment and package handling.

In agriculture, tactile sensing addresses the challenge of delicately harvesting produce. Robots equipped with these sensors can grasp a piece of fruit and assess its firmness to determine ripeness, mimicking the gentle squeeze of a human hand. This not only automates a labor-intensive process but also helps reduce food waste by ensuring that produce is picked at its optimal stage.

Challenges and Current Limitations

Durability Wear and Calibration

One of the most significant technical hurdles facing tactile sensing is creating sensors that can withstand the rigors of industrial environments. A sensor on a factory robot may need to perform millions of grasp cycles in the presence of dust, moisture, and temperature fluctuations. Ensuring that the sensor’s performance does not degrade over time due to wear and tear is a major engineering challenge, as is the need for stable, long-term calibration to maintain accuracy.

Many advanced sensor designs, particularly those using soft materials, are susceptible to mechanical fatigue, puncture, and drift in their baseline readings. The development of robust packaging and self-calibration algorithms is crucial for making tactile sensing a truly reliable industrial technology. Without longevity and stability, the potential benefits of tactile data are undermined by high maintenance costs and inconsistent performance.

Data Processing and Real Time Control

The sheer volume and velocity of data generated by high-resolution tactile sensors present a considerable computational challenge. A vision-based tactile sensor, for instance, can produce an image-like data stream at hundreds of frames per second. Processing this information and translating it into actionable feedback for a robot’s control loop—all within milliseconds—requires significant onboard processing power and highly efficient algorithms.

Integrating this high-frequency feedback into a robot’s control system is not trivial. It requires a tight coupling between the sensor hardware and the robot’s motion planner to enable immediate reactions, such as adjusting grip force to prevent an object from slipping. Overcoming the latency between sensing, processing, and actuation is key to unlocking the full potential of dynamic tactile feedback.

Cost and Scalability

Market adoption of advanced tactile sensing has been hindered by significant cost and scalability obstacles. Many state-of-the-art sensors are expensive to produce, often requiring specialized materials and complex fabrication processes. This high unit cost can make it economically unfeasible to deploy tactile-enabled robots at a large scale, limiting their use to high-value applications or research settings.

Furthermore, manufacturing these intricate sensors reliably and consistently in large quantities remains a challenge. As the demand for physically intelligent robots grows, the industry needs to find pathways to mass-produce tactile sensors affordably without compromising performance. Achieving economies of scale is essential for making tactile sensing a ubiquitous feature in robotics rather than a niche capability.

Future Outlook and Long Term Impact

The future of robotic tactile sensing is inextricably linked to the pursuit of human-level dexterity in robotic manipulation. Ongoing breakthroughs in materials science are expected to yield self-healing and more durable sensor materials, addressing the critical challenge of longevity. Concurrently, the standardization of tactile hardware and data formats will likely accelerate research and development, creating a more cohesive ecosystem for an entire industry to build upon.

The long-term impact of tactile-enabled Physical AI on society and industry promises to be transformative. As robots gain the ability to skillfully and safely interact with the physical world, they will become capable of performing a vast new range of tasks in manufacturing, logistics, healthcare, and beyond. This will not only drive economic productivity but also open up new possibilities for how humans and machines collaborate to solve complex, real-world problems.

Conclusion

This review has examined the state of robotic tactile sensing, from its core technological principles to its emerging applications and persistent challenges. The analysis showed that while significant hurdles related to durability, data processing, and cost remain, the field is advancing rapidly. The integration of rich tactile data with machine learning is proving to be a watershed moment, enabling a new generation of robots with the capacity for intelligent physical interaction. The technology is no longer a theoretical curiosity but a critical component poised to unlock the full potential of Physical AI and redefine the future of automation across countless sectors.