The ongoing challenge of maintaining precise inventory control in vast, complex warehouses has long been a critical vulnerability in the global supply chain, a problem that traditional systems have struggled to resolve completely. Physical AI for inventory management represents a significant advancement in the logistics and supply chain sector. This review will explore the evolution of this technology, its key features, performance metrics, and the impact it has had on various industrial applications. The purpose of this review is to provide a thorough understanding of the technology, its current capabilities, and its potential for future development.

The Emergence of Physical AI in Logistics

The core principle behind “Physical AI” is a fundamental departure from conventional AI models trained on vast, publicly available internet data. Instead, this technology learns directly from the real-world physical environments it is designed to operate in. By leveraging millions of proprietary images and data points collected within warehouses, the AI develops a nuanced understanding of tangible operational challenges.

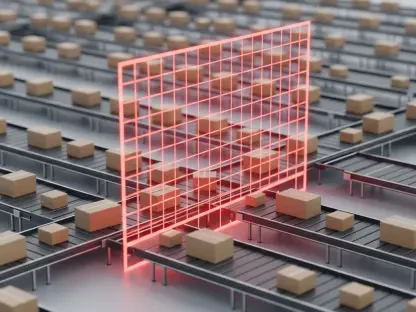

This approach was born out of the necessity to solve the persistent “blind spots” in supply chain visibility. Traditional inventory methods, whether manual counts or sensor-based systems, often fail to provide a complete and real-time picture of on-the-floor stock. Physical AI, embodied by autonomous robots, fills this gap by creating a direct, verifiable link between digital records and the physical reality of the warehouse, transforming abstract data into a reliable operational truth.

Core Technologies and System Architecture

Autonomous Robotics and Data Capture

The hardware foundation of this system consists of autonomous robots, typically drones, engineered to navigate the intricate and often challenging environments of modern warehouses. These robots operate without relying on conventional sensors like GPS or lidar, which can be unreliable indoors. Instead, they utilize advanced computer vision as their primary mode of perception and navigation.

This allows them to “see” and interpret their surroundings, identifying, counting, and verifying stock on shelves with remarkable precision. The ability to autonomously capture high-fidelity visual data across millions of square feet is the first crucial step in digitizing the physical state of the warehouse and creating a comprehensive inventory snapshot.

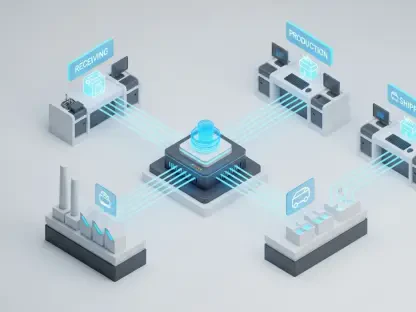

Proprietary AI Platform for Data Analysis

The raw visual data captured by the robots is processed by a sophisticated, AI-driven software platform. This proprietary system analyzes millions of warehouse images to identify products, read barcodes, and assess pallet conditions, achieving a level of detail and accuracy that far surpasses human capabilities. The platform’s intelligence lies in its ability to transform this unstructured visual information into structured, actionable business intelligence.

By contextualizing the data, the software provides a clear and current view of on-the-floor operations, flagging discrepancies, and feeding accurate information back into enterprise resource planning systems. This analytical engine is the brain of the operation, converting what the robots see into what the business needs to know.

Recent Developments and Market Validation

The logistics industry is signaling strong confidence in Physical AI, evidenced by significant financial investment and accelerating market adoption. Recent funding milestones, including a $40 million Series B round that brought total capital raised to $74 million, underscore investor belief in the technology’s scalability and long-term value. This financial backing is a direct response to tangible market momentum.

Over the past year, the technology has seen its operational footprint double and its bookings grow by 250%, indicating robust customer demand. This rapid expansion reflects a market that is not only ready for but is actively seeking out advanced solutions to solve decades-old inventory management challenges.

Real-World Applications and Performance Metrics

Deployment in Major Industrial Enterprises

Physical AI is no longer a theoretical concept but an operational standard for some of the world’s leading logistics and manufacturing companies. Industry giants like GEODIS, NFI Industries, and Kwik Trip have integrated this technology into their daily warehouse inventory management processes. Its adoption by these major players demonstrates its viability and effectiveness in large-scale, high-stakes environments.

The successful implementation across these enterprises validates the technology’s ability to meet rigorous industrial demands for reliability, accuracy, and integration, proving its value beyond pilot programs and into core operational workflows.

Quantifiable Gains in Accuracy and Efficiency

The impact of Physical AI is most clearly seen in its measurable performance improvements. Companies deploying the technology report achieving near-perfect inventory accuracy levels of 99.9%, a metric that is exceptionally difficult to reach with manual methods. This precision dramatically reduces costly errors such as stockouts and overstocking.

Furthermore, the automation of the counting process has led to a reduction in manual labor costs by as much as 80%, freeing up human workers for more value-added tasks. This efficiency translates into a fivefold increase in overall productivity, with most clients reporting a full return on their investment in less than six months.

Implementation Challenges and Limitations

Despite its proven benefits, the widespread adoption of Physical AI is not without its hurdles. Scaling the technology across hundreds of facilities globally presents significant operational and technical challenges, requiring robust deployment strategies and support teams capable of managing large-scale enterprise rollouts.

Integrating the system with a diverse array of existing enterprise resource planning (ERP) and warehouse management systems (WMS) is another critical complexity. Ensuring consistent performance and accuracy in varied physical environments—from cold storage to facilities with non-standard racking—demands continuous adaptation and refinement of both the hardware and the AI models.

Future Outlook and Strategic Vision

Evolving from Visibility to Autonomous Orchestration

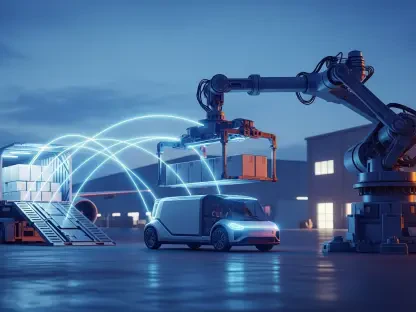

The future trajectory for Physical AI extends far beyond simply providing real-time inventory visibility. The ultimate goal is to evolve the system from a reactive monitoring tool into a proactive, autonomous management platform. This shift involves leveraging the vast amounts of data collected to predict inventory needs, identify potential disruptions, and orchestrate stock movements without human intervention.

This vision of “full autonomous orchestration” aims to transform warehouse management from a process of responding to problems to one that preemptively solves them, creating a truly intelligent and self-regulating logistics environment.

Building the Intelligence Layer for the Modern Supply Chain

In the long term, the strategic objective for Physical AI is to establish itself as the foundational “system of record” for the physical world of warehouses and factories. By creating a centralized intelligence layer, the technology has the potential to become the single source of truth for inventory data, driving decision-making not just within a single facility but across the entire global supply chain.

This vision positions the technology as a core component of the modern digital supply chain, providing the crucial data infrastructure needed to enable greater resilience, efficiency, and intelligence from the factory floor to the end customer.

Concluding Assessment

Physical AI for inventory management demonstrates a transformative impact on logistics and supply chain operations. The technology successfully marries autonomous robotics with sophisticated AI analytics to solve the enduring problem of inventory inaccuracy. Its ability to deliver near-perfect accuracy, reduce labor costs, and provide a rapid return on investment confirms its powerful value proposition. While implementation at scale presents challenges, the technology’s strong market validation and clear strategic vision position it to become a cornerstone of the modern, data-driven supply chain.