The logistics industry is undergoing a profound technological transformation in 2024, driven by the need to enhance efficiency, sustainability, and customer satisfaction. This major shift is characterized by the adoption of advanced technologies that promise to reshape every aspect of logistics operations. As more companies recognize the necessity of integrating these cutting-edge solutions, the logistics landscape is poised to experience significant improvements. From automation and robotics to AI and blockchain, these innovations are set to redefine logistics processes and create new standards for productivity and transparency.

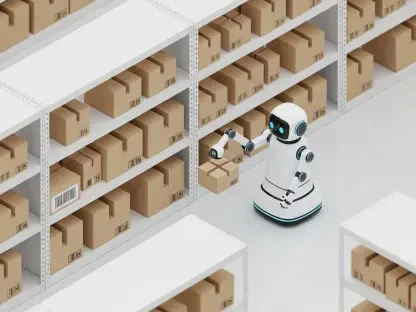

Warehouse Technology Trends 2024: Automation and Robotics

One of the most impactful trends in logistics technology is the advancement of automation and robotics in warehouse operations. Automation is viewed as the foremost innovation in the field, with a significant percentage of logistics companies planning substantial investments in these technologies. Automated picking systems, robotic palletizers, and Autonomous Guided Vehicles (AGVs) are revolutionizing warehouse functions by reducing human errors, expediting processes, and cutting labor costs. The value of automation extends beyond merely replacing manual labor, aiming to optimize every facet of warehouse operations, yielding substantial productivity gains and throughput improvements.

Companies like Amazon and Alibaba are at the vanguard of this trend, utilizing extensive robot fleets in their fulfillment centers to streamline sorting, picking, and packing tasks. Similarly, DHL’s investment of $15 million in automating its North American warehouses underscores its commitment to maintaining its logistical leadership. By embracing these advancements, logistics providers can achieve faster and more efficient operations, ultimately leading to enhanced customer satisfaction and competitive advantage. Mike Field, CEO of Boston Dynamics, emphasizes that automation’s true potential lies in comprehensively improving the warehouse ecosystem, thereby enhancing overall business performance.

Transportation Technology Trends 2024: AI and Machine Learning

AI and ML are pivotal to the modern logistics landscape, transcending their status as mere buzzwords to become critical components of logistics operations. AI-driven algorithms analyze historical and real-time data to uncover patterns and make intelligent decisions that enhance efficiency and cut costs. These technologies are revolutionizing various logistics functions, such as route optimization and demand forecasting. AI-powered systems like UPS’s ORION have notably reduced delivery mileage and improved service levels, highlighting the potential for significant cost savings and operational efficiency.

DHL’s “Resilience360” platform, leveraging AI for demand forecasting, route optimization, and warehouse automation, exemplifies AI’s transformative potential in logistics. As AI and ML technologies continue to advance, their integration into logistics operations will deepen, driving further improvements in cost-efficiency and customer service. This technological progression allows for more precise and agile responses to market demands, enabling companies to stay ahead of the curve in a highly competitive landscape. Scott Price, President of UPS International, notes that the ongoing evolution of these technologies will continue to improve logistics operations, ultimately benefiting companies and their customers.

Supply Chain Technology Trends 2024: Blockchain

Blockchain technology is making strides in logistics by enhancing transparency and security. The blockchain supply chain market is projected to grow substantially, driven by the technology’s ability to provide an unprecedented level of transparency. Blockchain offers the promise of a tamper-proof digital ledger for every transaction, ensuring secure, easily traceable records of a product’s origin, manufacturing details, and ownership history. This capability is particularly valuable in industries where transparency and trust are paramount, such as food and pharmaceuticals.

Vincent Clerc, CEO of Maersk, underscores blockchain’s potential to revolutionize logistics by offering a clear and reliable means of tracking goods throughout the supply chain. Maersk’s TradeLens platform, developed in partnership with IBM, has already succeeded in reducing paperwork and improving data visibility across the supply chain. This enhanced transparency simplifies compliance processes and mitigates the risk of fraud. By adopting blockchain technology, logistics companies can foster stronger relationships with their partners and customers, building a foundation of trust and reliability that translates into long-term success.

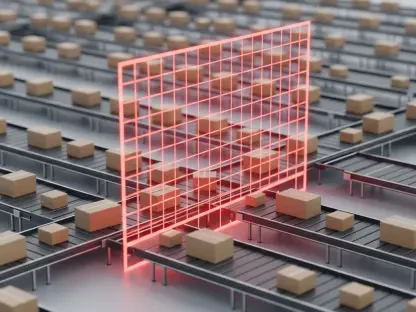

Internet of Things (IoT) in Logistics 2024: Enhanced Visibility and Efficiency

IoT technology is profoundly reshaping the logistics landscape by enabling real-time tracking of goods throughout the supply chain. By attaching sensors, tags, and trackers to shipments, pallets, and containers, companies can achieve unprecedented visibility into their operations. This wealth of data allows for more precise monitoring and management, ultimately leading to improved operational efficiency and reduced energy consumption. Such innovations are crucial for reducing waste and lowering costs, enhancing the overall sustainability of logistics operations.

Jean-Pascal Tricoire, CEO of Schneider Electric, emphasizes how IoT is revolutionizing logistics by providing continuous, real-time insights into supply chain dynamics. Companies like Volvo and Nissan are leveraging IoT to enhance logistics operations, including vehicle shipment monitoring and warehouse management. As more companies adopt IoT technology, significant improvements in supply chain visibility and efficiency are expected, resulting in more responsive and agile logistics processes. This technological shift underscores the importance of data-driven decision-making in modern logistics and its role in achieving sustainable growth.

AR and VR in Supply Chain Management 2024: Training and Workflow Optimization

AR and VR technologies are emerging as powerful tools for training and workflow optimization in logistics. These innovations allow employees to gain hands-on experience in a controlled environment, reducing the risks associated with real-world operations. By incorporating AR and VR into their training programs, companies can ensure that their workforce is better prepared to handle complex logistics tasks, ultimately enhancing safety and productivity.

Xavier Garijo, Global Managing Director of DB Schenker, highlights the transformative impact of AR and VR in logistics training. These technologies enable workers to follow picking and packing processes with minimal errors, improving overall productivity. Walmart’s use of VR for training, including simulations of peak scenarios like Black Friday sales, demonstrates this technology’s potential to enhance employee performance and retention. The adoption of AR and VR in logistics not only improves training efficiency but also enhances workflow optimization, leading to more precise and streamlined operations.

Autonomous Vehicles and Drones: The Future of Transportation

Autonomous vehicles and drones are set to revolutionize transportation in logistics, promising reduced delivery times, lower costs, and enhanced safety by minimizing human error. These technologies represent a significant leap forward in logistics operations, enabling companies to achieve greater efficiency and reliability in their delivery processes. The deployment of autonomous vehicles and drones is expected to transform last-mile delivery, making it faster and more cost-effective.

Sundar Pichai, CEO of Alphabet, foresees autonomous vehicles as the future of logistics. Alphabet’s Waymo project explores deploying self-driving trucks for package delivery, aiming to reduce labor costs and increase efficiency. Similarly, Walmart’s successful completion of over 6,000 drone deliveries across seven U.S. states showcases drones’ potential for last-mile delivery. These advancements highlight the growing importance of autonomous technologies in logistics and their potential to reshape the transportation landscape.

Digital Twins: Virtual Modeling for Real-World Optimization

Digital twin technology involves the creation of virtual models of physical assets and processes, enabling real-time monitoring and optimization. This technology is increasingly important in logistics, facilitating the simulation of warehouse operations, route optimization, and predictive maintenance. Digital twins provide logistics companies with a powerful tool to identify bottlenecks and optimize processes before they escalate into significant issues, ultimately enhancing overall efficiency.

Tim Scharwath, CEO of DHL Global Forwarding, underscores how digital twins help achieve heightened efficiency by providing enhanced process visibility and predictive maintenance. DHL’s adoption of digital twins has resulted in significant reductions in supply chain interruptions, demonstrating the technology’s potential to improve logistics operations. As digital twin technology continues to evolve, its integration into logistics processes will become increasingly essential, enabling companies to achieve greater precision and operational excellence.

Final Thoughts

The logistics industry is experiencing a significant technological shift in 2024, driven by the demand for increased efficiency, sustainability, and customer satisfaction. This transformative period is marked by the integration of state-of-the-art technologies poised to revolutionize all facets of logistics operations. As more companies realize the importance of adopting these advanced solutions, the logistics sector is set for major enhancements. The introduction of automation and robotics, along with the implementation of AI and blockchain technology, is expected to overhaul logistics processes. These advancements will not only raise standards for productivity but also ensure greater transparency across operations. The changes will ultimately benefit the entire supply chain, from warehousing and transportation to last-mile delivery, by optimizing performance and enhancing service levels. With the progressive adoption of these innovations, the logistics industry is on the brink of a new era, setting benchmarks that will likely influence other sectors as well.