That out-of-stock notification for your favorite pair of jeans might feel like a personal inconvenience, but for retail giants like Gap Inc., it is a critical signal of a global supply chain under unprecedented strain. Navigating a world where pandemics, geopolitical shifts, and extreme weather can fracture logistics networks overnight has become the definitive business challenge. In response, Gap has embarked on a fundamental redesign of its operations, moving from a model built on lean efficiency to one architected for enduring resilience.

When Fashion Meets a Fractured Global Supply Chain

The familiar rhythm of seasonal retail has been irrevocably disrupted. The long-held assumption that goods would flow predictably from factories to storefronts has been shattered by years of volatility. This new reality forces brands to confront a difficult truth: the hyper-efficient, cost-optimized supply chains of the past are too brittle for the modern world. The central challenge is no longer a simple trade-off between speed and cost but a complex equation that must also solve for risk, flexibility, and reliability.

This operational shift is driven as much by internal necessity as by external pressure. Today’s consumers expect immediate availability, a demand that runs counter to the realities of global instability. For a company like Gap, the ability to meet this expectation is not just a logistical goal; it is a core component of its brand promise. Failing to have the right product in the right place at the right time erodes customer trust and directly impacts the bottom line, turning supply chain strategy into a critical competitive advantage.

Architecting Agility Inside Gap’s Strategic Overhaul

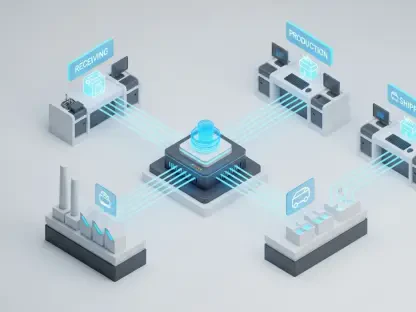

At the heart of Gap’s transformation is a multi-pronged strategy designed to build a more adaptable and robust operational backbone. The first pillar is a deliberate move toward diversification and automation. By widening its geographical sourcing and manufacturing footprint, the company mitigates the risks associated with dependency on any single region. This diversification eliminates potential single points of failure, ensuring that a disruption in one area does not cripple the entire network.

Simultaneously, Gap is investing heavily in automation within its distribution centers. This technology serves a dual purpose. While it drives efficiency, its primary strategic value lies in creating flexibility. Automated systems allow the network to scale operations dynamically, enabling it to pivot between the high-speed demands of a limited-edition product launch and the high-volume requirements of a major value promotion. This agility allows each brand under the Gap Inc. umbrella to tailor its logistics to its specific market strategy.

Another critical pillar is the shift from transactional vendor agreements to deep, strategic partnerships. The company has redefined its relationship with key providers like UPS, viewing them not as suppliers but as collaborators in solving complex logistical challenges. This approach fosters joint innovation and allows Gap to leverage the specialized expertise and scale of its partners. A prime example is the company’s use of the UPS and Happy Returns network, which provided an immediate, scalable solution for e-commerce returns that would have been far more difficult and costly to build in-house.

A C-Suite View on Building Managerial Muscle

According to Chief Supply Chain Officer Sally Gilligan, technology and partnerships are only part of the solution. The most crucial transformation is cultural—building what she calls “managerial muscle” within the organization. This refers to the ability of internal teams to make difficult, real-time trade-off decisions as global conditions shift. It requires empowering employees with the data and authority to act decisively when confronted with unforeseen challenges.

This internal revolution is underpinned by a disciplined focus on prioritization. Instead of attempting to pursue dozens of initiatives at once, the strategy centers on executing a few key projects flawlessly. This concentrated effort builds organizational confidence and ensures that resources are deployed for maximum impact. For Gap’s leadership, this internal agility is the ultimate safeguard, enabling the company to navigate uncertainty not just by reacting to disruptions but by proactively managing them.

The Resilience Playbook and Its Actionable Lessons

Gap’s journey offers a clear framework for any business seeking to fortify its operations against unpredictability. The first step is to conduct a thorough vulnerability audit of the entire sourcing and manufacturing network to identify potential weak points. This assessment provides the foundation for building a more diversified and resilient supplier base.

From there, the focus shifts to strategic investments. Implementing technology that enables flexibility and scalability, rather than just cost reduction, is paramount. This should be complemented by cultivating deep, problem-solving relationships with key logistics partners who can act as extensions of the internal team. Ultimately, the most powerful tool is an empowered workforce, armed with the data and authority to make agile decisions that keep the supply chain moving in a constantly changing world. The transformation at Gap demonstrated that true resilience was built not just from concrete and code, but from a strategic re-evaluation of partnerships and people.