The U.S. electronics manufacturing sector is witnessing a transformative shift as global players seek to establish a stronger foothold in American markets, driven by the need to meet rising consumer demand for high-tech products. With foreign direct investment pouring into states like Texas, a new era of localized production is emerging. Pegatron Corporation, a leading Taiwan-based electronics manufacturer, stands at the forefront of this trend with its announcement of a groundbreaking $35 million facility in Georgetown, Texas. This development not only highlights the state’s growing status as a tech hub but also raises critical questions about how international firms can navigate the complexities of the U.S. manufacturing landscape. What does this mean for the industry, local economies, and the future of tech innovation?

Overview of Pegatron and the U.S. Electronics Manufacturing Landscape

Pegatron Corporation, headquartered in Taiwan, ranks among the world’s top electronics manufacturers, specializing in a wide range of products from laptops and smartphones to gaming consoles and automotive systems. Established as a key player in the global supply chain, the company has built a reputation for innovation and scalability, serving major tech brands across continents. Its decision to enter the U.S. market underscores a strategic pivot toward localized production to enhance efficiency and customer responsiveness.

The U.S. electronics manufacturing industry holds a significant position in the global market, contributing billions annually to the economy while driving advancements in consumer electronics, automotive technology, and hardware solutions. Despite historical challenges such as offshoring, recent years have seen a resurgence of interest in domestic production, fueled by geopolitical shifts and supply chain disruptions. Key segments like smartphones and electric vehicle components are experiencing rapid growth, reflecting the sector’s adaptability to evolving demands.

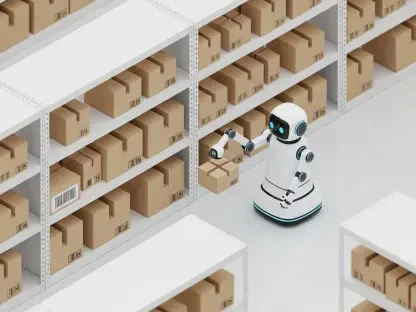

This landscape is shaped by major domestic and international players, with foreign investment playing a pivotal role in job creation and technological transfer. Cutting-edge developments in automation, artificial intelligence, and sustainable practices are propelling the industry forward, supported by federal and state policies aimed at fostering innovation. Texas, in particular, has emerged as a magnet for such investments, thanks to its business-friendly environment and robust infrastructure, setting the stage for companies like Pegatron to thrive.

Strategic Expansion: Pegatron’s Move to Georgetown, Texas

Key Details of the New Facility

Pegatron’s $35 million investment in Georgetown, Texas, marks a historic milestone as the company establishes its first U.S. manufacturing plant. Construction of the state-of-the-art facility is already underway, with operations expected to commence within the next year. This plant will focus on high-tech manufacturing, producing a diverse array of products including laptops, smartphones, and gaming consoles to cater directly to the American market.

The strategic location in Georgetown offers proximity to major tech corridors and logistics hubs, enabling Pegatron to streamline distribution and reduce lead times for U.S. customers. By bringing production closer to end users, the company aims to improve service delivery and respond more swiftly to market trends. This move also reflects a broader industry shift toward regional manufacturing to mitigate global supply chain risks.

Economic and Community Impact

The economic ripple effects of this investment are poised to be substantial for Georgetown and the surrounding Williamson County. Pegatron anticipates creating at least 100 high-tech jobs within the first three years of operation, with potential for further expansion as production scales. These positions will span engineering, manufacturing, and management roles, offering opportunities for skilled workers in the region.

Beyond job creation, the facility is expected to stimulate local businesses, from suppliers to service providers, fostering a vibrant economic ecosystem. Texas’s reputation as a tech hub gains further traction with such investments, positioning the state as a leader in advanced manufacturing. Local projections suggest that Williamson County could see sustained growth in tax revenues and infrastructure development as a direct result of this project.

Challenges in Establishing a U.S. Manufacturing Presence

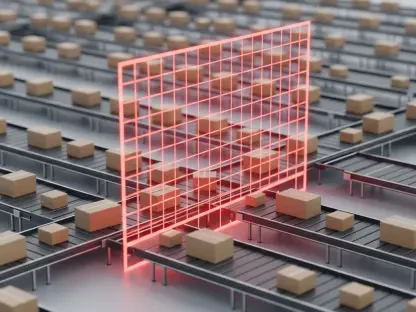

Navigating the U.S. manufacturing environment presents a unique set of challenges for Pegatron, starting with the intricacies of supply chain logistics. Establishing reliable networks for raw materials and components in a new market requires significant coordination, especially given the current global shortages and transportation bottlenecks. Adapting to these constraints will test the company’s operational resilience.

Regulatory compliance poses another hurdle, as U.S. standards for manufacturing, labor, and environmental practices differ markedly from those in other regions where Pegatron operates. Ensuring adherence to these rules while maintaining cost efficiency demands meticulous planning and investment in training programs. Additionally, competition from established domestic manufacturers necessitates a deep understanding of local consumer preferences to tailor products effectively.

To address these obstacles, Pegatron is likely to pursue strategic partnerships with local firms and invest in cutting-edge technology to boost productivity. Workforce development initiatives, such as collaborations with Texas educational institutions, could help build a skilled talent pool. By leveraging automation and data analytics, the company can also optimize processes to stay competitive in a demanding market.

Economic Policies and Support for Foreign Investment in Texas

Texas has cultivated a reputation as a welcoming destination for foreign direct investment, thanks to a combination of favorable economic policies and a pro-business climate. Tax incentives, streamlined permitting processes, and access to a robust workforce have made the state an attractive choice for international companies like Pegatron. These policies are designed to encourage long-term growth in high-value industries such as technology and manufacturing.

State officials have been vocal in their support for this venture, with Adriana Cruz, Executive Director of the Texas Economic Development & Tourism Office, highlighting Texas’s leadership in advanced technology and its top ranking for foreign investment in the U.S. Local leaders, including Georgetown Mayor Josh Schroeder and Williamson County Judge Steve Snell, have also expressed enthusiasm, emphasizing the transformative potential for community development and the region’s appeal as a tech manufacturing center.

Infrastructure investments and economic development programs further facilitate such projects, providing the necessary framework for companies to establish operations swiftly. These efforts not only benefit incoming firms but also contribute to the sustainability of Texas’s tech ecosystem. The synergy between state and local support underscores a commitment to fostering innovation and economic diversification over the coming years.

Future Outlook for Pegatron and Texas’s Tech Sector

Pegatron’s entry into the U.S. market through its Georgetown facility offers a promising platform for future expansion. As the company gains traction, there is potential to scale operations, introduce new product lines, and deepen ties with American tech giants. This foothold could serve as a model for other international manufacturers considering similar moves, amplifying Texas’s allure as a global tech destination.

Emerging trends in electronics manufacturing, such as increased automation and a focus on sustainable practices, are likely to shape Pegatron’s strategies moving forward. Consumer demand for locally made, eco-friendly high-tech products continues to grow, presenting opportunities to align production with these preferences. Innovations in smart manufacturing and renewable energy integration could further enhance the company’s market position.

Texas stands to solidify its role as a leader in the global tech arena, with foreign investments like Pegatron’s driving economic momentum. Despite potential headwinds from global economic conditions, the state’s proactive approach to fostering innovation ensures resilience. The convergence of talent, infrastructure, and policy support points to a bright horizon for both Pegatron and the broader tech sector in the region.

Final Reflections

Looking back, Pegatron’s establishment of its first U.S. plant in Georgetown, Texas, marked a significant chapter in the evolution of the state’s tech landscape. The initiative brought tangible benefits, from job creation to economic growth, while highlighting the power of strategic foreign investment. It also underscored the importance of collaboration between international firms and local stakeholders in overcoming operational challenges.

Moving forward, the focus should shift to sustaining this momentum through continued investment in workforce training and technological innovation. Policymakers and industry leaders must prioritize infrastructure enhancements to support scaling operations. Exploring partnerships with academic institutions can further bridge skill gaps, ensuring a steady pipeline of talent.

Additionally, attention to sustainable manufacturing practices will be critical to meeting future consumer expectations and regulatory demands. By building on this foundation, Texas can reinforce its status as a tech powerhouse, while companies like Pegatron can expand their impact. The path ahead calls for adaptability and foresight to capitalize on emerging opportunities in a dynamic global market.