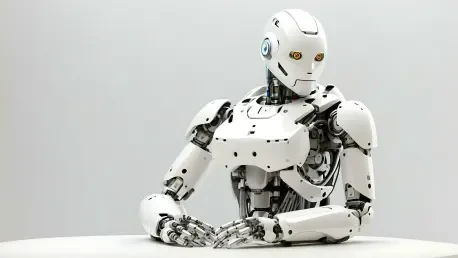

On the verge of an industrial transformation, one might wonder what role human workers will play as robotics technology accelerates. What if the workforce of the future isn’t human at all, but rather humanoid robots executing tasks with unmatched precision? A recent survey suggests that humanoid robots in industrial settings have increased by nearly 50% over the past decade. This surge raises the question: how far can these robotic entities push the boundaries of human effort?

Beyond Human Labor: Robots Driving Efficiency

In the evolving landscape of manufacturing and warehousing, efficiency reigns supreme. With global labor shortages and rising operational costs, businesses are under immense pressure to do more with less. Enter humanoid robots, programmed to meet these demands. Combining AI intelligence with the form of a human, these machines are designed to perform repetitive tasks tirelessly while enhancing adaptability in working environments. Today, many companies consider these robots as a viable solution to sustain productivity amidst the challenges of a dwindling workforce.

Design Choices: Wheels or Legs for Better Output?

The very structure of humanoid robots is a topic of rigorous debate. Should these robots roll on wheels or walk on legs? Each design serves distinct purposes. Robots with legs, designed to mimic humans, navigate complex terrains and environments where wheels fall short. Notable examples include articulated robots with enhanced lifting abilities that allow them to manage heavy loads efficiently, thus boosting productivity. Nevertheless, safety remains a top concern, especially in warehouses teeming with human workers. Despite sophisticated collision avoidance systems, perfecting human detection is an ongoing struggle to ensure seamless human-robot coexistence.

Real-world Applications: Problems Solved

Melonee Wise of Agility Robotics notes that “humanoid robots are solving practical industrial problems.” Consider a case where a large-scale manufacturing plant successfully integrated these robots, resulting in a 30% increase in output and a significant decrease in operational costs. Research findings indicate that companies adopting humanoid robots can see a return on investment within three years, provided they tackle integration challenges effectively. These success stories underscore the potential impact of robotics in transforming operations and enhancing profitability.

Guiding Industrial Decisions: Human-Robot Synergy

For businesses contemplating the integration of humanoid robots, a strategic approach is essential. Balancing complex interactions between humans and robots remains critical to ensuring that operations are not only safe but also highly efficient. A recommended framework involves assessing specific industrial needs and choosing robots with the appropriate capabilities—whether that’s advanced mobility, superior load handling, or exceptional adaptability to diverse environments. By focusing on synergy rather than competition, businesses can harness the full potential of robotic technology.

Charting New Paths Forward

Looking ahead, it is evident that humanoid robots are pushing the boundaries of manufacturing and logistics. Their unique skills redefine industry norms and offer unparalleled avenues for innovation. However, achieving the ideal balance between human workers and robotic counterparts requires careful planning and a commitment to ongoing development. As technology advances, industries explore more sophisticated systems, making the prospects for automation truly exciting. The era of humanoid robotics has truly begun—and its implications for the future could be boundless.