The rise of e-commerce has revolutionized shopping experiences, presenting consumers with a convenient way to purchase products from the comfort of their homes. However, this convenience has led to a significant increase in product returns, posing a considerable challenge for retailers. Effectively managing these returns is crucial for mitigating their impact on profitability and maintaining efficient operations. Reverse logistics, the process of handling product returns from customers back to retailers or manufacturers, involves a complex series of activities that can add layers of complexity and cost to the supply chain. This article explores strategies for optimizing reverse logistics, focusing on managing e-commerce returns and minimizing their economic and operational burdens.

Understanding Reverse Logistics

Reverse logistics encompasses the process of transporting goods from customers back to retailers or manufacturers and requires navigating significant complexities compared to the traditional supply chain. In a typical supply chain model, raw materials and finished products flow downstream to customers. Conversely, reverse logistics operates against this flow, akin to swimming against a river’s current, which adds layers of complexity and cost. The growth of online shopping has dramatically increased the volume of returns, creating new challenges for retailers. Handling and processing returned goods demand significant resources, such as transportation, inspection, refurbishing, storage, labor, and processing capacities. As the volume of returns escalates, particularly during peak shopping periods, these challenges become even more pronounced.

Returns in the e-commerce sector tend to have a higher rate compared to those purchased in physical stores, further complicating the reverse logistics process. This higher return rate is attributed to several factors, including customers’ inability to physically inspect products before purchase and the ease of initiating returns online. This situation necessitates robust strategies to manage the influx of returned items efficiently. By understanding the intricacies of reverse logistics and the challenges posed by increased return volumes, retailers can develop comprehensive solutions to address these issues.

Economic Impacts of Returns

Returns can have severe economic implications for retailers, primarily due to the various costs associated with handling and processing them. These costs include transportation, inspection, refurbishing, and warehousing, which can easily surpass the profits generated from the original sale of the product. For instance, the expenses related to shipping and processing returned items can account for a significant percentage of the original sale price, sometimes ranging from 20% to 30%. This highlights the pressing need for efficient reverse logistics strategies to minimize these economic burdens.

Moreover, the unpredictability and high volume of returns, especially during peak shopping seasons, further strain retailers’ resources. The fluctuating return rates make it challenging to manage inventory and allocate resources effectively. Additionally, the costs associated with processing returns can be variable and difficult to forecast, adding another layer of complexity to financial planning for retailers. To combat these challenges, implementing streamlined reverse logistics processes and leveraging technology to automate handling tasks can significantly reduce costs and improve overall efficiency. By addressing these economic impacts, retailers can better manage their resources and maintain profitability in the face of rising return volumes.

Leveraging Automation

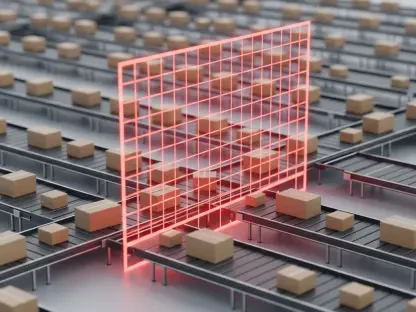

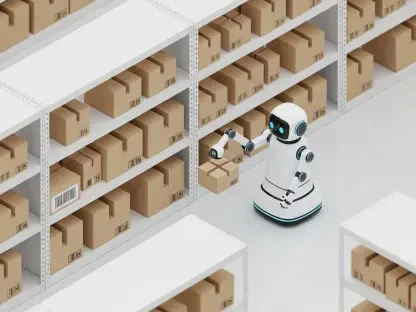

Automation technology plays a pivotal role in optimizing reverse logistics, offering solutions that can greatly enhance efficiency and reduce operational burdens. Investing in automation can streamline the returns process, minimize errors, and lower labor costs, thus addressing some of the major challenges in reverse logistics. Automated solutions, such as those offered by Loop Returns, enable real-time inventory tracking and automate various processing events, significantly reducing manual effort and enhancing operational efficiency. Automation also provides additional benefits, such as preventing returns fraud and abuse by incorporating checks and balances into the returns process.

Furthermore, automated systems facilitate quicker processing of returned items, ensuring that products are inspected, refurbished, and restocked promptly. This accelerated turnaround time helps maintain inventory levels and reduces the need for extensive storage facilities, further cutting down costs. Additionally, automated data collection and analytics enable retailers to gain insights into return patterns, identify recurring issues, and develop targeted strategies to mitigate them. As a result, investments in automation technology can yield substantial benefits, enhancing the overall efficiency of reverse logistics and improving the bottom line for retailers.

Customized Customer Experiences

Retailers are increasingly recognizing the importance of providing customized experiences for different customer segments to manage returns effectively and improve customer satisfaction. Tailoring the returns process to specific customer needs can help balance operational efficiency with customer expectations. For loyal customers, providing expedited returns services can enhance their shopping experience and foster brand loyalty. Conversely, other customers may have to wait for refunds or exchanges until the returned items are inspected, allowing retailers to control costs associated with returns.

These customized solutions enable retailers to manage customer expectations more effectively while also streamlining the returns process. By segmenting customers based on purchase behavior and return history, retailers can allocate resources more efficiently and prioritize high-value customers. Additionally, offering personalized communication and support during the returns process can improve customer satisfaction and minimize potential friction. Implementing these strategies not only helps manage the operational challenges associated with returns but also contributes to building a positive customer relationship, ultimately enhancing profitability and brand reputation.

Keep-it Policies and Returnless Refunds

The introduction of returnless refunds has significantly transformed the returns landscape, offering an innovative approach to handling low-value items. Amazon’s adoption of returnless refunds in 2017 allowed customers to keep items that are not worth the cost of processing a return, and this policy has since been widely adopted across the retail industry. Keep-it policies are generally applied to items with low resale value or minimal potential for refurbishing and resale. This approach helps reduce transportation, labor, and restocking expenses, consequently cutting down the overall costs associated with returns.

However, keep-it policies also carry risks, such as potential abuse and revenue loss. Customers may exploit the policy by initiating returns for items they do not intend to keep, resulting in increased returns and decreased profitability. To mitigate these risks, retailers must carefully evaluate which items qualify for returnless refunds and implement robust monitoring mechanisms. Despite these challenges, the benefits of keep-it policies in terms of cost reduction and operational efficiency make them an attractive option for managing returns in the e-commerce sector. By leveraging these strategies, retailers can better navigate the complexities of reverse logistics and minimize the financial impact of returns.

Controlled Friction in Returns

Introducing controlled friction in the returns process, such as return fees, is a strategy employed by retailers to manage return volumes and associated costs. By charging return fees, retailers can discourage customers from purchasing items they are unsure about, ultimately reducing the frequency of returns. Brands like Zara have successfully implemented return fees, demonstrating that this approach can help maintain profitability despite high return rates. Controlled friction in the returns process also encourages customers to make more deliberate purchasing decisions, resulting in a lower incidence of returns.

However, return fees must be carefully balanced to avoid deterring customers from future purchases or negatively impacting brand perception. Transparent communication about return policies and fees is essential to managing customer expectations and minimizing dissatisfaction. Additionally, providing incentives for customers to return unwanted items in-store rather than online can further reduce the costs associated with returns. This approach helps streamline the returns process and allows for quicker inspection and restocking of returned items. Overall, controlled friction strategies can effectively manage return volumes and costs, contributing to a more sustainable reverse logistics process.

Accurate Product Information

Providing detailed and accurate product information is a critical strategy for reducing return rates and enhancing customer satisfaction. By offering comprehensive product descriptions, sizing charts, and other relevant information, retailers empower customers to make informed purchasing decisions. This reduces the likelihood of returns due to inaccuracies or mismatched expectations. Investing in technology that assists customers with product fitting and quality assessment, such as virtual try-on tools and augmented reality applications, can further decrease return rates.

Accurate product information also contributes to building customer trust and brand loyalty, as customers are more likely to be satisfied with their purchases when they receive products that meet their expectations. Additionally, clear and precise information about product features, materials, and care instructions can help customers make better choices, reducing the need for returns. By prioritizing the accuracy of product information, retailers can improve the overall shopping experience, decrease operational strain associated with returns, and enhance profitability.

Strategic Implementation

Effective reverse logistics requires a strategic approach that integrates technology and analytical tools to streamline processing, understand return patterns, and make data-driven decisions. Retailers must prioritize returns management as an operational priority to navigate the challenges posed by high return volumes and ensure efficient handling of returned goods. By leveraging technology, such as automated returns solutions and data analytics, retailers can gain insights into return trends, identify recurring issues, and develop targeted strategies to address them.

Strategic implementation also involves aligning returns policies with overall business objectives and customer experience goals. This includes adopting practices like controlled friction, keep-it policies, and customization of the returns process to balance operational efficiency with customer satisfaction. Additionally, continuous monitoring and evaluation of returns processes enable retailers to adapt to changing market dynamics and customer behavior. By integrating strategic implementation into their operations, retailers can enhance both customer satisfaction and profitability, effectively managing the complexities of reverse logistics and optimizing their e-commerce returns process.

Conclusion

The surge in e-commerce has transformed how people shop, offering a convenient way for consumers to buy products without leaving their homes. Yet, this convenience has sparked a notable rise in product returns, creating significant challenges for retailers. Managing these returns efficiently is essential for controlling costs and ensuring smooth operations. Reverse logistics, the process of returning products from customers to retailers or manufacturers, entails a series of intricate activities that can introduce added complexity and expense to the supply chain.

To address these challenges, retailers must implement effective strategies for optimizing reverse logistics. This involves improving the management of e-commerce returns and reducing the associated financial and operational burdens. One approach is to streamline the returns process through better customer service and more flexible return policies. Additionally, employing advanced technology such as automated returns processing and data analytics can help predict return trends and enhance efficiency.

Proper inventory management, clear communication with customers, and effective collaboration with logistics partners are also critical in handling returns. By focusing on these strategies, retailers can mitigate the impact of returns on profitability and maintain efficient operations, ultimately enhancing the overall shopping experience.