With decades of experience spanning the supply chain and delivery sectors, Rohit Laila has established himself as a leading voice in the logistics industry, known for his deep expertise and passion for technological innovation. Today, we delve into the strategic expansion of Challenge Group’s GSA partnership into Eastern Europe. We’ll explore the thinking behind this move, how it enhances the company’s central Liege hub, the pivotal role of new aircraft in their future plans, and the sophisticated technology that underpins their complex global operations.

Your expansion added seven Eastern European countries to your GSA agreement. What specific opportunities did you identify in markets like Poland and Romania, and what were the key steps involved in launching GSA services across this new region?

We saw a tremendous, untapped potential in these markets. Countries like Poland and Romania are experiencing an industrial renaissance, and we knew there was a significant demand for transporting core items like heavy industrial machinery, engines, and drilling equipment. This wasn’t just a hunch; it was a calculated move based on clear market signals. Launching was a meticulous process. It began with establishing strong local teams through our ECS Group partnership, who understand the nuances of each country. From there, we integrated our commercial processes and operational planning, ensuring a seamless flow of information and cargo from day one. It’s incredibly rewarding to see this strategic vision come to life and connect these vibrant economies to our global network.

The article states this move broadens the feeder capture area for your Liege hub. Can you walk us through how new cargo from a country like Hungary is integrated into existing freighter flights to the US or China, and what impact this has on your operational metrics?

Absolutely. Think of our Liege hub as the heart of our European operations, and these new Eastern European countries are the vital arteries feeding into it. For example, a large piece of automotive manufacturing equipment from Hungary is trucked to Liege, where our ground team orchestrates its transfer onto a waiting Boeing 747 freighter. This process is a masterclass in precision timing, ensuring that cargo arrives just in time to be loaded for a long-haul flight to Hong Kong or the US. Operationally, this has a massive positive impact. It significantly increases our load factors and network density, which are critical metrics for profitability. Every piece of new cargo from these feeder markets makes our entire network stronger and more efficient.

As you prepare to add converted Boeing 777-300ERSFs, how do these aircraft specifically support your planned expansion into Asia and South America? What key operational advantages do they offer over your current 747 and 767 fleet for these new long-haul routes?

The B777-300ERSF is a true game-changer for us; it’s not just an additional aircraft, it’s a key that unlocks our future. The primary advantages are range and efficiency. These converted freighters can fly longer routes with a full payload more economically than our current 747 fleet. This means we can launch direct, non-stop services to major hubs in Asia and, for the first time, South America, without the need for costly and time-consuming technical stops. For our customers, this translates to faster, more reliable service. For us, it means opening up lucrative new trade lanes and cementing our position as a truly global carrier.

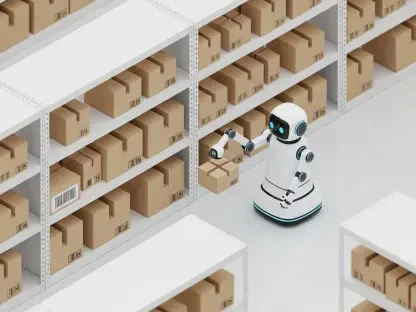

You handle diverse freight from industrial machinery to live animals. How do you leverage CargoTech software like SkyPallet and Apollo to manage these different cargo streams, and could you share an anecdote where this technology streamlined a particularly complex shipment from your network?

Technology is the central nervous system of our operation. Without it, managing such diverse cargo would be impossible. Apollo gives us the high-level business intelligence to see trends and make strategic decisions, while a tool like SkyPallet is our secret weapon on the ground. I recall a particularly complex shipment that included sensitive, temperature-controlled pharmaceuticals alongside oversized aerospace parts. Normally, this is a planner’s nightmare. But using SkyPallet, we were able to digitally model the entire cargo hold, ensuring the delicate pharma shipment was properly positioned and secured, while also maximizing every square inch of space for the bulky parts. The technology allowed us to build the perfect load plan before the cargo even hit the warehouse floor, saving immense time and preventing any potential conflicts on the aircraft.

What is your forecast for the air cargo market in Eastern Europe over the next five years, especially considering current geopolitical and economic shifts?

Despite the current global uncertainties, I am decidedly optimistic about Eastern Europe. The region’s industrial base is robust and continues to grow, and we’re seeing a strong trend of near-shoring as companies diversify their supply chains. I predict that over the next five years, this region will transition from being primarily a feeder market to a significant origin and destination point in its own right. There will be increased demand for both exports of high-value manufactured goods and imports of components and consumer products. This is why our strategic expansion now is so crucial; we are positioning ourselves at the forefront of this economic evolution, ready to grow alongside these dynamic markets.