The trucking and logistics sector demonstrated remarkable resilience during the 2024 holiday season, driven by strong consumer spending and the expansion of e-commerce. Despite a broader freight downturn, the sector’s performance was bolstered by strategic planning, technological advancements, and robust consumer demand.

Strong Consumer Spending and E-commerce Expansion

Record Holiday Retail Sales

The National Retail Federation reported that holiday retail sales were expected to rise between 2.5% and 3.5% over the previous year. This increase was fueled by a near-record 197 million people shopping between Thanksgiving and Cyber Monday, showcasing enduring consumer enthusiasm for holiday shopping. The DHL 2024 Peak Season Shipping Survey supported these findings, with 48% of small and medium-sized enterprises anticipating increased holiday sales over 2023. Additionally, this upward trend in holiday sales is not just a testament to consumer fervor but also reflects the resilience and strategic foresight of retailers who prepare months in advance.

Such robust sales figures underscore the critical role of the trucking and logistics industry in fulfilling the demands of a thriving retail environment. The near-record shopping activity during key dates like Thanksgiving and Cyber Monday provided clear evidence of the strong consumer appetite for holiday shopping. Each purchase translated into a shipment, making seamless and efficient logistics a necessity. The robust engagement of consumers during these shopping holidays created simultaneous peaks in freight demand, compelling the logistics sector to optimize its operations for maximum efficiency.

Robust Consumer Demand

Consumer spending remained strong throughout the holiday season, driven by factors such as low unemployment, robust real disposable income, and a solid e-commerce infrastructure. Mazen Danaf, Staff Applied Scientist and Economist at Uber Freight, highlighted the healthy state of the U.S. consumer, citing record levels of online shopping during Black Friday and Cyber Monday as evidence of sustained consumer demand. This consistent consumer activity was further bolstered by a solid digital marketplace where e-commerce companies had enhanced their platforms to handle increased traffic and transactional activities seamlessly.

The investment in e-commerce infrastructures—ranging from user-friendly websites to efficient payment gateways—ensured consumers enjoyed a smooth shopping experience. The logistics sector had to consistently support these demand patterns by speeding up order processing and delivery timelines, emphasizing the importance of last-mile delivery capabilities. Moreover, this demand was not sporadic but marked a steady increase as consumers became more comfortable with online shopping, expecting faster, more accurate delivery services. This trend of heightened consumer demand necessitated a strategic alignment within the logistics sector, prompting enhanced coordination and technological integration to keep up with the surges in shopping activity.

Early Preparation and Strategic Planning

Retailers’ Early Inventory Pull-Forward

Retailers began their preparations in the spring, with October marking a critical deadline due to potential port strikes. Noah Hoffman, Vice President of Retail Logistics at C.H. Robinson Worldwide, noted that retailers strategically mitigated risks by pulling inventory forward as early as June. This extended the peak shipping season beyond its usual duration, ensuring a fluid supply chain despite a three-day port strike. By commencing their preparations months ahead, retailers were able to spread out their inventory management tasks, alleviating pressure on supply chains and reducing the likelihood of stockouts.

This proactive strategy of early pull-forward allowed retailers to anticipate market fluctuations and manage inventory more effectively, thus ensuring the availability of products when consumer demand peaked. The collaborative efforts among stakeholders, such as logistics companies, suppliers, and retailers, were vital to making this strategy successful. Extending the peak season also aligned logistical operations with retail strategies, providing a buffer against disruptions and ensuring that warehouses operated at optimal capacity despite potential external challenges. This demonstrated how strategic planning and foresight could mitigate risks and ensure the timely availability of goods during high-demand periods.

Impact of Port Strikes and Supply Chain Fluidity

The early inventory pull-forward strategy allowed the supply chain to remain fluid, ensuring the timely movement of goods from warehouses to final destinations. This proactive approach helped retailers navigate potential disruptions, maintaining efficient delivery services throughout the holiday season. Retailers and logistics providers coordinated closely to develop contingency plans that could quickly adapt to sudden changes, whether due to port strikes or other unforeseen events that could disrupt the supply chain.

This level of preparedness ensured that even when disruptions did occur, the impact on end consumers was minimal. Effective communication between all parties involved played a crucial role in maintaining the flow of goods. By leveraging data analytics and real-time tracking technologies, logistic service providers could monitor and manage inventory levels dynamically, thereby reducing delays and optimizing transportation routes. This adaptability was key to the logistics sector’s ability to handle increased volumes and customer expectations, ensuring that the holiday shopping experience remained largely unaffected by external challenges.

Adaptation to Increased Shipping Volumes

Investment in Logistics Infrastructure

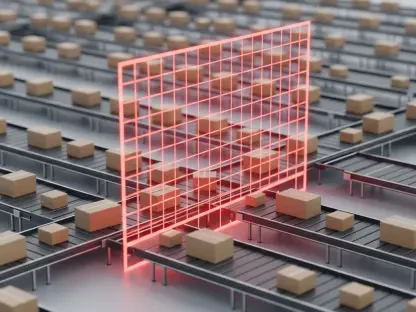

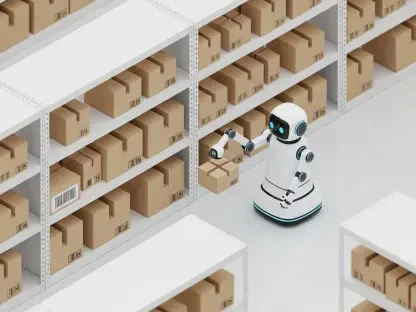

The industry adapted well to the increased volume of last-mile shipping, a trend catalyzed by the pandemic. Companies invested in faster and more efficient order fulfillment methods, including new distribution centers, warehouses, and leveraging technology for route optimization. Jenna Slagle, Senior Data Analyst at Project44, emphasized that these investments ensured low delivery times, indicative of the sector’s improved logistics capabilities. As the pandemic accelerated the shift towards e-commerce, the logistics sector had to react quickly to enhance their infrastructure to cater to the surging demands.

The establishment of new distribution centers closer to urban areas allowed for quicker dispatches and reduced delivery times, meeting customer expectations for speed. Additionally, advancements in warehouse automation, such as the use of robots and AI in sorting and packaging, significantly reduced manual errors and increased efficiency. Companies also sought partnerships with tech firms to integrate sophisticated software for real-time tracking and route optimization, making last-mile delivery more predictable and reliable. These efforts collectively enabled the logistics sector to cope with the spike in shipments, ensuring that goods reached customers swiftly and in perfect condition.

Technological Advancements and Route Optimization

Technological advancements played a crucial role in managing increased shipping volumes. Companies utilized technology for route optimization, enhancing efficiency and reducing delivery times. This investment in technology ensured that the logistics sector could meet the growing demands of the holiday season effectively. Route optimization software helped in identifying the most efficient paths, considering variables such as traffic, weather, and vehicle load capacities, which contributed to better resource utilization and lower operational costs.

The integration of Internet of Things (IoT) devices in delivery vehicles enabled real-time monitoring of shipments, providing logistic service providers with actionable data to tweak operations on the fly. Moreover, the use of big data analytics allowed for better forecasting of demand patterns, enabling companies to plan inventory and transportation needs more accurately. The adaptation of these cutting-edge technologies marked a significant evolution in the logistics sector, allowing it to not only keep pace with increasing volumes but also enhance overall service quality and delivery precision during peak periods.

Timing and Distribution of Shopping Activity

Early Start to Holiday Shopping

The holiday shopping period started earlier than usual due to the shortened interval between Thanksgiving and Christmas. Pawan Joshi, Executive Vice President of Products and Strategy at E2open, mentioned that this shift allowed for a more even distribution of shopping activity, avoiding the usual spikes around key dates like Cyber Monday. Starting sales promotions and marketing campaigns earlier in the season helped in spreading out the consumer demand, reducing the stress on supply chains that typically experience bottlenecks during sudden peaks.

This spread of shopping activities enabled logistics providers to manage shipments more effectively, ensuring that deliveries remained timely and efficient even as overall volumes increased. Consumers were encouraged to shop earlier through strategic marketing initiatives and attractive discounts, which contributed to a steadier flow of orders. Consequently, the logistics sector could optimize its resources, and warehouse and delivery operations, maintaining service levels without compromising on quality. This early commencement of the shopping season also provided more time for retailers to replenish inventory, ensuring product availability and preventing stockouts during critical shopping periods.

Even Distribution of Freight Movement

The earlier start to holiday shopping resulted in a more even distribution of freight movement, reducing pressure on the logistics sector. This even distribution helped the industry manage increased volumes more efficiently, ensuring timely delivery of goods throughout the holiday season. With a more constant flow of orders, logistics companies could better plan their workforce, vehicle deployment, and route scheduling, enhancing the overall efficiency of their operations.

Moreover, this even distribution of activities reduced the risk of delays and congestion at key transit points, such as ports, warehouses, and distribution centers. The logistics network experienced fewer bottlenecks, allowing for smoother operations and increased reliability. This approach also facilitated improved communication and coordination among various stakeholders in the supply chain, from manufacturers to retailers, ensuring that everyone was aligned and working towards the common goal of delivering products on time. The result was a highly responsive and adaptive logistics sector capable of meeting the demands of the holiday season with agility and precision.

Handling Global Supply Chain Disruptions

Preparedness for Supply Chain Challenges

Global supply chain disruptions, such as the Suez Canal bottlenecks, affected freight movement. However, companies were better prepared to handle these challenges. Dan Spitale, Vice President of UPS Capital, pointed out that consumer concerns about delays remained significant, but the industry’s ability to offer diverse and robust shipping options helped mitigate these worries. By diversifying their supply chains and building in redundancies, companies could shift routes and adjust plans to keep goods moving despite major disruptions.

Additionally, the use of advanced analytics and scenario planning enabled logistics providers to anticipate and respond to potential issues more effectively. Companies invested in supply chain risk management tools that provided real-time visibility into potential bottlenecks, allowing for proactive adjustments. These efforts were complemented by strategic collaborations with international partners to ensure alternative routes and resources were available if traditional paths became obstructed. This level of preparedness underscored the logistics sector’s resilience and capacity to maintain service levels even under challenging circumstances, reassuring consumers of timely deliveries despite global supply chain challenges.

Resilience and Adaptability of the Logistics Sector

The trucking and logistics industry displayed remarkable resilience during the 2024 holiday season, despite the broader freight downturn. This robust performance was driven by several key factors, such as strong consumer spending and the continual growth of e-commerce. The industry’s ability to weather the challenging conditions was not only a testament to its adaptability but also to the effectiveness of its strategic planning efforts. Companies within this sector invested in technological advancements, which played a significant role in optimizing operations and handling the increased demand efficiently. Additionally, robust consumer demand during the holiday season provided a substantial boost. E-commerce expansion meant more goods needed to be transported, leading to increased activity in the trucking sector. This convergence of factors enabled the trucking and logistics industry to not only survive but thrive during a period that was otherwise challenging for the broader freight market. The industry’s agility and forward-thinking strategies ensured it could meet the heightened demands of the holiday season, securing its position as a critical component of the modern economy.