Imagine a life-saving vaccine, developed halfway across the globe, needing to reach a remote hospital within 48 hours while maintaining a strict temperature range of 2–8°C to remain effective, as any deviation could render it useless, jeopardizing countless lives. This scenario underscores the critical importance of the air cargo cold chain, a technology-driven logistics solution that ensures the rapid, safe transport of temperature-sensitive goods. This review dives into the intricacies of this transformative system, exploring its core features, real-world performance, and the profound impact it has on industries ranging from pharmaceuticals to agriculture.

Understanding the Air Cargo Cold Chain

The air cargo cold chain represents a specialized segment of logistics dedicated to the transportation of perishable and high-value goods under tightly controlled temperature conditions. Unlike traditional shipping methods, this system integrates air freight to prioritize speed, addressing the urgent demands of time-critical shipments. Its emergence reflects a growing need for reliable solutions in a globalized economy where goods like fresh produce or biologics must often travel vast distances without compromising quality.

At its core, this technology leverages a network of advanced tools and collaborative partnerships to maintain product integrity. From refrigerated containers to real-time monitoring systems, every element is designed to mitigate risks associated with temperature fluctuations. This capability positions air cargo as an indispensable asset for sectors where delays or deviations can lead to significant financial losses or health risks.

The significance of this logistics model extends beyond mere transportation; it serves as a lifeline for industries dependent on precision and expediency. By bridging geographical barriers with unmatched efficiency, the air cargo cold chain has redefined how temperature-sensitive products are handled, ensuring that critical items reach their destinations in optimal condition.

Core Features of Air Cargo Cold Chain Operations

Temperature Control and Monitoring Systems

Maintaining precise temperature ranges during transit stands as a cornerstone of air cargo cold chain operations. Advanced refrigeration units and insulated containers are deployed to safeguard products like pharmaceuticals, which often require conditions as specific as 2–8°C. These systems are engineered to counteract external variables such as ambient heat or humidity, preserving the efficacy of sensitive cargo throughout the journey.

Equally vital are the monitoring technologies that provide continuous oversight. Sensors embedded in shipments transmit real-time data on temperature and environmental conditions, alerting logistics teams to any anomalies. This level of vigilance ensures that deviations are addressed promptly, minimizing the risk of spoilage or degradation for high-stakes goods like vaccines or fresh seafood.

The reliability of these systems has become a benchmark for quality in cold chain logistics. With the integration of cloud-based platforms, stakeholders can access detailed reports and historical data, fostering transparency and trust. Such innovations underscore the commitment to product safety, making temperature control a defining feature of this technology.

Speed and Time-Critical Logistics

Speed serves as another pivotal attribute of the air cargo cold chain, distinguishing it from slower, ground-based alternatives. Air freight drastically reduces transit times, often delivering goods within hours rather than days, which is crucial for items with short shelf lives. This rapid delivery model caters to urgent needs, such as emergency medical supplies or seasonal floral shipments during peak holidays.

Operational strategies further enhance this focus on expediency. Time-critical charters and dedicated flight schedules ensure that shipments bypass typical delays associated with standard cargo routes. Logistics providers coordinate meticulously with airports and ground handlers to streamline processes, shaving off valuable time at every stage of the supply chain.

The implications of this speed are profound for industries reliant on just-in-time delivery. For instance, pharmaceutical companies can maintain lean inventories while still meeting patient needs, knowing that critical drugs can arrive swiftly. This capability not only boosts operational efficiency but also strengthens market responsiveness in a competitive landscape.

Technological Advancements Driving Efficiency

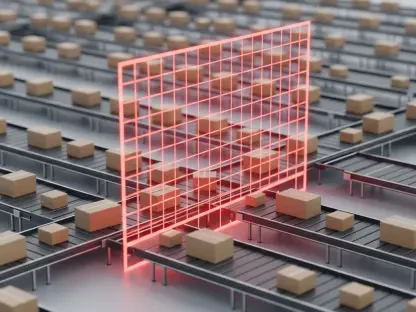

The air cargo cold chain has been propelled forward by cutting-edge technological innovations that enhance control and visibility. Real-time tracking systems, powered by IoT devices, allow shippers to monitor shipments at every step, providing instant updates on location and condition. This transparency empowers decision-making, enabling quick interventions if issues arise during transit.

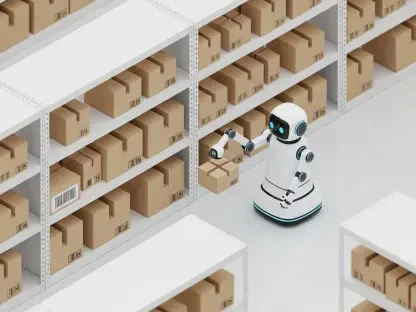

Automation also plays a significant role in optimizing operations. Automated sorting and loading systems at cargo hubs reduce human error and accelerate handling times, ensuring that temperature-sensitive goods spend minimal time outside controlled environments. Such advancements contribute to a seamless flow of goods, even under tight deadlines.

Data-driven solutions are shaping the future trajectory of this logistics model. Predictive analytics, for instance, can forecast potential disruptions like weather delays, allowing for proactive rerouting. These tools not only improve efficiency but also reduce costs, making the technology more accessible to a broader range of industries and applications.

Real-World Applications and Industry Impact

Across diverse sectors, the air cargo cold chain delivers tangible benefits by ensuring product quality and availability. In pharmaceuticals, it facilitates the global distribution of temperature-critical medications, such as insulin or biologics for autoimmune treatments, directly impacting patient outcomes. The ability to transport these items swiftly and safely has become a cornerstone of modern healthcare supply chains.

Agriculture and floriculture also reap significant rewards from this technology. Perishable goods like fresh fruits or cut flowers, often tied to seasonal demand, rely on expedited air transport to reach markets in peak condition. This ensures that consumers enjoy high-quality products, while producers minimize waste and maximize profitability through timely deliveries.

Humanitarian aid represents another critical application, where rapid deployment of medical supplies or food can mean the difference between life and death. Air cargo cold chain operations enable emergency responses to crises, delivering refrigerated vaccines or nutritional supplements to disaster-stricken areas. This adaptability highlights the technology’s role in enhancing global supply chain resilience.

Challenges and Limitations to Address

Despite its strengths, the air cargo cold chain faces notable hurdles that temper its scalability. Maintaining consistent temperature control across varying climates and transit points remains a technical challenge, as even brief exposure to adverse conditions can compromise cargo. Continuous investment in robust infrastructure is essential to address these vulnerabilities.

Regulatory compliance adds another layer of complexity, with differing standards across international borders often causing delays or additional costs. Harmonizing these regulations requires coordinated efforts among governments and industry players, a process that can be slow and resource-intensive. Navigating this landscape demands strategic planning and adaptability from logistics providers.

High operational costs further limit accessibility, particularly for smaller shippers or regions with underdeveloped aviation networks. The expense of specialized equipment, fuel, and trained personnel can be prohibitive, creating disparities in adoption. Efforts to innovate cost-effective solutions and expand global reach are underway, but progress remains uneven across markets.

Looking Ahead: The Future of Air Cargo Cold Chain

Reflecting on this review, the air cargo cold chain proves to be a game-changer in temperature-controlled logistics, blending speed, precision, and technology to meet the demands of a fast-paced world. Its ability to safeguard high-value goods across vast distances stands out as a testament to human ingenuity in overcoming logistical barriers. The impact on industries like healthcare and agriculture is undeniable, ensuring that critical products reach their destinations without compromise.

Moving forward, stakeholders should prioritize sustainable practices, exploring energy-efficient refrigeration and greener fuel options to reduce environmental footprints. Investing in automation and predictive tools will further enhance efficiency, while global collaboration can streamline regulatory challenges. Expanding access to underserved regions through innovative partnerships promises to democratize this technology, ensuring broader benefits.

As the landscape evolves, continuous adaptation will be key to unlocking the full potential of air cargo cold chain logistics. Embracing emerging technologies and fostering industry-wide cooperation can address existing limitations, paving the way for a more resilient and inclusive supply chain. This journey, though complex, holds immense promise for transforming how temperature-sensitive goods are transported worldwide.