The persistent hum of American factory floors is changing, not just with the sound of new machinery but with the quiet urgency of a workforce gap that traditional automation has struggled to fill. As manufacturers grapple with persistent labor shortages and a strategic push to bring production back to domestic soil, a new generation of intelligent robotics is emerging as a critical solution. Munich-based RobCo, an industrial automation company, is positioning itself at the forefront of this shift, armed with significant new capital and a vision for a more autonomous production environment.

An End to Manual Programming for Factory Robots

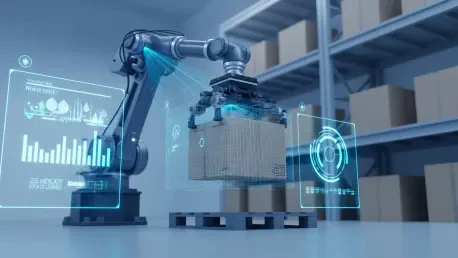

For decades, deploying industrial robots has been a complex, time-intensive process requiring specialized programmers to write intricate code for every task. This high barrier to entry has limited automation to large-scale, repetitive operations, leaving smaller and more dynamic processes untouched. RobCo aims to dismantle this paradigm by introducing robots that can learn through demonstration and self-correction, effectively eliminating the need for manual coding.

This approach dramatically accelerates deployment times, allowing manufacturers to adapt to changing production demands with unprecedented agility. Instead of weeks of programming, a robot can be taught a new task—like palletizing boxes or assembling components—in a matter of hours. This shift democratizes automation, making it accessible to a wider range of businesses and applications, particularly those in small to medium-sized enterprises that form the backbone of the US industrial base.

Meeting a New Reality in American Manufacturing

The American manufacturing sector is navigating a perfect storm of economic pressures. A significant skills gap, compounded by an aging workforce, has left countless positions unfilled, while the strategic imperative to reshore production introduces new layers of operational complexity. These challenges cannot be solved by simply adding more traditional machinery; they require a more flexible and intelligent approach to automation.

RobCo’s strategy directly targets these pain points. By offering easily deployable and adaptable robotic solutions, the company provides a viable path for manufacturers to scale operations without being entirely dependent on a shrinking pool of skilled labor. This technology supports the reshoring movement by enabling domestic factories to compete more effectively on a global scale, enhancing productivity and resilience in the supply chain.

The Foundation of RobCo’s Platform: What is Physical AI

At the core of RobCo’s innovation is “physical AI,” a term describing the fusion of advanced perception, motion planning, and self-learning capabilities within a robotic system. Unlike conventional robots that follow rigid, pre-programmed paths, RobCo’s machines use sensors and AI to perceive their environment, understand complex tasks, and refine their actions over time. This creates a system that is not just automated but truly autonomous.

This vertically integrated platform combines proprietary hardware and software into a cohesive, full-stack solution. By controlling the entire technology stack, RobCo ensures seamless integration and continuous improvement. This allows its robots to not only perform tasks but to optimize them, learning from each cycle to become more efficient and reliable in real-world production settings.

Inside the $100 Million Bet on Automating the Ordinary

A recent $100 million Series C funding round, co-led by Lightspeed Venture Partners and Lingotto Innovation, validates the market’s confidence in RobCo’s vision. With backing from other major investors like Sequoia Capital, this capital infusion is more than a financial milestone; it is a clear endorsement of the company’s approach to solving fundamental manufacturing challenges. The investment signals a broader industry recognition that AI-driven robotics is the next frontier in industrial automation.

CEO Roman Hölzl articulated the company’s mission as “automating the ordinary, so humans can do the extraordinary.” This philosophy underscores a focus on augmenting human labor, not replacing it entirely. By handling mundane, repetitive, and physically demanding tasks, the robots free up human workers to focus on more complex, creative, and value-added responsibilities, ultimately fostering a more skilled and dynamic workforce.

From Munich to Austin: A Strategy for the US Factory Floor

With its European roots firmly established, RobCo has identified the United States as its primary growth market and is channeling its new resources accordingly. The company is actively scaling its enterprise deployments and deepening its presence from its hubs in San Francisco and Austin, positioning itself to serve the heart of American industry. This targeted expansion is a direct response to the high demand for automation solutions driven by the nation’s manufacturing renaissance.

The strategic push into the U.S. reflected a calculated effort to become the dominant AI robotics provider for manufacturers on both sides of the Atlantic. The substantial funding and focused market strategy were foundational steps that positioned RobCo not just as a technology provider, but as a key partner for American factories navigating the transition toward a more autonomous and resilient future. These moves established the groundwork for what could be a significant transformation on the factory floor.