The once-unchanging landscape of the warehouse loading dock is now at the epicenter of a technological revolution, driven by advanced robotics designed to tackle one of the most physically punishing jobs in the supply chain. Robotic trailer unloading represents a significant advancement in the logistics sector, moving beyond simple automation to introduce intelligent systems capable of navigating complex, real-world environments. This review will explore the evolution of this technology, its key features, performance metrics, and the impact it has had on warehouse operations, with a focus on the “Scoop” system developed by FedEx and Berkshire Grey. The purpose of this review is to provide a thorough understanding of the technology, its current capabilities, and its potential future development in addressing industry-wide challenges.

The Emergence of Autonomous Unloading Solutions

Robotic trailer unloading systems are advanced physical AI solutions engineered to autonomously empty truck trailers and shipping containers with minimal human intervention. They emerged not just as a matter of convenience but as a direct response to long-standing challenges in logistics, particularly the hazardous, unpredictable, and physically demanding nature of manual unloading. This task has historically been a major source of workplace injuries and a significant operational bottleneck, dependent on manual labor in often harsh conditions.

By automating this critical first step in the receiving process, the technology aims to create a fundamentally safer work environment for employees while simultaneously boosting operational efficiency. Its introduction is particularly relevant in the current technological landscape, where the relentless growth of e-commerce volumes and persistent labor shortages have created a pressing need for more resilient, predictable, and scalable supply chain solutions. The shift toward autonomous unloading is therefore not merely an upgrade but a strategic necessity for modern logistics operators.

Key Technologies of the Scoop System

Physical AI and Bulk-Handling Capabilities

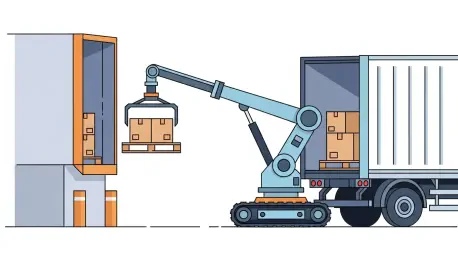

The core of the “Scoop” system is its sophisticated “physical AI,” a technology that empowers the robot to perceive its environment, make real-time decisions, and safely maneuver within the tight confines of a trailer. Unlike earlier robotic systems that often required structured environments or specific package orientations, this AI enables the unit to handle the chaotic and unpredictable state of a fully loaded trailer. Its innovative bulk-handling approach further distinguishes it from its predecessors. Rather than picking and placing individual pieces, it gathers large groups of packages at once, a method that allows it to efficiently empty trailers at a high and consistent throughput.

This function is particularly significant as it directly addresses a key performance metric for modern logistics hubs: the creation of a steady, continuous inbound flow of packages. By smoothing out the peaks and valleys of manual unloading, the system helps optimize downstream sorting and processing operations. The ability to autonomously navigate into a trailer, perform its task, and exit without assistance represents a substantial leap forward in warehouse automation, transforming a variable process into a reliable one.

Seamless Integration and Safety-First Design

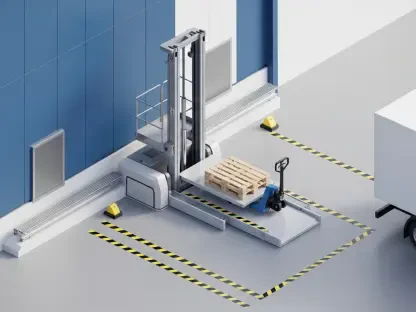

A crucial feature of the “Scoop” system is its design for minimal facility impact, which allows for seamless integration into existing FedEx operations without requiring major, cost-prohibitive infrastructure changes. This “plug-and-play” philosophy is critical for widespread adoption, as it lowers the barrier to entry for facilities looking to modernize their inbound processes. The robot is engineered to work alongside human teams, complementing their roles rather than seeking to entirely replace them.

This collaborative approach is reinforced by the system’s “safety-first” design principle. While the robot operates autonomously, the architecture allows for human assistance to handle unique exceptions, such as oversized or irregularly shaped items that fall outside the robot’s standard operating parameters. This technical aspect ensures operational continuity and fosters a work environment where technology supports the human workforce, offloading the most strenuous tasks while relying on human cognitive flexibility to solve complex edge cases.

Recent Developments and Strategic Collaborations

The most significant recent development in this space is the launch of “Scoop” as the product of a multi-year, dedicated collaboration between logistics giant FedEx and AI robotics provider Berkshire Grey. This partnership has evolved substantially, starting with the deployment of Robotic Product Sortation and Identification (RPSi) systems in 2021 for sorting small packages. The relationship deepened in 2022 with an agreement for broader AI robotic development, culminating in the advanced unloading solution available today.

This trajectory highlights a clear and growing trend toward deep, strategic partnerships between industry leaders and specialized technology firms. Instead of pursuing off-the-shelf solutions, companies like FedEx are co-developing bespoke systems tailored to solve their most pressing and complex operational problems. This collaborative model accelerates innovation by combining deep domain knowledge from the logistics provider with cutting-edge AI and robotics expertise from the technology partner, resulting in more effective and integrated solutions.

Application in High-Volume Logistics Hubs

The primary real-world application for this technology is in high-volume parcel hubs, where trailer unloading has long been a critical bottleneck that dictates the pace of the entire facility. FedEx is deploying the “Scoop” system to directly address this challenge, targeting the point where operational efficiency and employee well-being intersect. The implementation has a dual impact that serves the company’s core operational goals and its commitment to its workforce.

First, it enhances employee safety by mitigating one of the most physically strenuous jobs in the logistics chain, reducing the risk of injuries associated with repetitive lifting and awkward postures in confined spaces. Second, it boosts operational efficiency by ensuring a steady and predictable flow of goods into the sorting facility, which allows for better planning and utilization of downstream automated systems. Following a successful pilot program, the first systems are now in full operation, marking a pivotal moment in the modernization of inbound logistics.

Current Challenges and Limitations

Despite its advancements, the primary challenge for robotic trailer unloading technology remains the immense variability of freight. Handling the vast assortment of package types, shapes, weights, and materials found in unsorted trailers is a formidable task. Moreover, the unpredictable nature of how packages are stacked and shift during transit presents a significant technical hurdle for autonomous navigation and manipulation, requiring the AI to adapt to countless potential scenarios.

Another obstacle is ensuring the system can be deployed, maintained, and serviced at a massive scale without disrupting existing workflows. The transition from a pilot program to a network-wide deployment requires robust support infrastructure and training programs for the on-site teams who will work alongside the robots. Ongoing development efforts are critical for refining the technology’s ability to handle a greater variety of goods and for streamlining the maintenance process to ensure high uptime and reliability before widespread adoption becomes a reality.

The Future of Inbound Logistics Automation

The outlook for robotic trailer unloading is exceptionally promising, with the technology poised to become a new standard in inbound logistics over the next decade. Future developments will likely focus on increasing the speed, agility, and versatility of the robots, enabling them to handle an even wider range of goods and trailer configurations with greater precision. As the technology matures, we can expect to see enhanced capabilities, such as the ability to identify and sort packages at the point of unloading.

Potential breakthroughs in physical AI, computer vision, and sensor technology could ultimately lead to fully autonomous “dock-to-stock” processes, where goods are unloaded, identified, and moved to their next destination with no human touchpoints. The long-term impact on the industry will be a fundamental shift in warehouse operations. This will transform a physically taxing, injury-prone job into a technology-supported role focused on system oversight and exception handling, ultimately creating safer, more efficient, and more resilient supply chains.

Summary and Overall Assessment

This review highlighted robotic trailer unloading as a transformative technology that directly addresses critical safety and efficiency needs within the modern logistics industry. The FedEx and Berkshire Grey “Scoop” system exemplifies the current state-of-the-art, effectively combining advanced physical AI with a practical, safety-oriented design that integrates into existing operational footprints. While challenges in handling extreme package variability and ensuring scalability remain, the technology’s potential to create a consistent inbound flow and dramatically reduce physical strain on employees was clearly demonstrated. Its overall impact has set a new benchmark for one of the most challenging aspects of warehouse operations, marking a significant and necessary step forward in the ongoing evolution of supply chain automation.