The relentless demand for faster turnarounds and flawless traceability has pushed many contract packers to a critical breaking point, where traditional spreadsheets and manual tracking systems are no longer viable business tools. This review examines Nulogy’s Shop Floor Solution, a digital platform positioned as a strategic investment for contract packers navigating these intense modern industry pressures. It assesses how the solution addresses critical challenges like the need for real-time visibility and operational efficiency, using the recent digital transformation at Complete Co-packing as a practical case study. The central objective is to determine if this technology provides the necessary competitive edge in a market that demands unprecedented speed, quality, and robust audit trails.

Why Co-Packers Are Turning to Digital Solutions

The modern contract packing landscape is defined by escalating complexity, from an ever-growing number of SKUs to stringent client requirements for transparency. For companies like Complete Co-packing, a firm with over three decades of experience, the limitations of manual, spreadsheet-driven operations became a significant barrier to growth. Such legacy systems inherently create information silos, delay decision-making, and introduce a high risk of human error, making it difficult to maintain the agility needed to satisfy demanding brand partners.

This pressure is compelling a widespread industry shift toward digitalization. The move away from pen-and-paper processes is no longer just about improving efficiency; it is a fundamental requirement for survival and growth. By embracing digital solutions, co-packers aim to gain a unified, real-time view of their operations, which is essential for proactive problem-solving, ensuring compliance, and delivering the high level of service that secures long-term partnerships.

Dissecting the Nulogy Shop Floor Solution

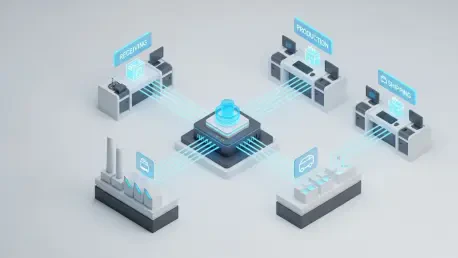

Nulogy’s Shop Floor Solution is a purpose-built digital platform designed specifically to meet the unique demands of contract packing and manufacturing environments. Its core function is to digitalize and automate key workflows across the entire production cycle. This includes everything from material scanning at receiving and tracking labor on the line to executing quality assurance checks and recording the creation of finished goods, all within a single, cohesive system.

The platform’s key selling point is its ability to provide a single source of truth through live dashboards and real-time data feeds, effectively replacing the fragmented and outdated manual processes that hinder many operators. It is intended to grant management immediate and clear visibility into job statuses, current inventory levels, and production throughput. Consequently, this empowers leaders to move from a reactive to a proactive management style, addressing potential issues before they escalate into costly problems.

Evaluating Nulogy’s Promised Performance and Impact

A primary promise of the platform is the delivery of complete operational transparency. By design, it eliminates information silos and provides stakeholders with live dashboards that offer an uninterrupted, real-time view of production progress. This visibility allows managers to identify potential bottlenecks as they form, monitor line performance against targets, and make informed adjustments on the fly, rather than waiting for end-of-shift reports to discover issues.

The solution aims to drive significant gains in production efficiency by automating previously manual tasks like labor tracking and material consumption logging. This automation not only accelerates processes but also drastically reduces the data entry errors common with spreadsheet-based systems. Furthermore, its integrated quality check protocols and comprehensive digital records strengthen traceability. This capability is critical for building robust audit trails, ensuring compliance with strict customer standards, and safeguarding brand integrity. The system also promises to enhance inventory management by using real-time scanning to maintain precise accuracy, thereby minimizing material waste and preventing stock-outs that can halt production.

Key Advantages and Potential Considerations

One of the most significant advantages of Nulogy’s platform is that it offers a specialized solution tailored to the distinct needs of the contract packing industry, unlike generic ERP modules that often require heavy customization. This focus allows for real-time visibility and granular control over shop floor operations, supporting faster and more effective responses to production issues. Moreover, the enhanced traceability and quality control features are designed to meet the increasingly stringent demands of both customers and regulatory bodies, providing a clear competitive differentiator.

However, organizations must also weigh potential considerations. The transition from legacy systems to a sophisticated digital platform requires substantial organizational change management, including comprehensive employee training to ensure user adoption and maximize the return on investment. The initial financial commitment for a specialized platform can also be more significant than that of a generic software module. Finally, the ultimate success of the implementation is heavily dependent on achieving a seamless integration with a company’s existing business systems, such as accounting and warehouse management, to create a truly unified operational ecosystem.

Final Assessment: A Necessary Leap Forward

Based on its targeted features and direct alignment with industry needs, Nulogy’s Shop Floor Solution represents a crucial tool for modernizing contract packing operations. For companies like Complete Co-packing, the move from inefficient manual processes to this integrated digital platform is not merely an upgrade but a foundational shift necessary for future competitiveness and sustainable growth. The system directly addresses the industry’s most pressing challenges by delivering real-time data, enhancing end-to-end traceability, and driving measurable improvements in efficiency. The assessment concludes that the solution is a highly valuable, strategic investment for co-packers committed to meeting the evolving demands of their clients and the market at large.

Recommendation for the Modern Co-Packer

The Nulogy Shop Floor Solution comes highly recommended for contract packing and manufacturing firms currently reliant on spreadsheets or disconnected legacy systems to manage their production environments. It is particularly beneficial for businesses aiming to sharpen their competitive advantage through superior quality control, verifiable traceability, and heightened operational agility. Before adoption, it is crucial for a company to conduct a thorough analysis of its existing workflows to map out a smooth integration path. Preparing teams for the digital transformation ahead through clear communication and robust training will be equally vital to unlocking the full potential of this powerful platform.