Amazon unveiled its cutting-edge robotic system, Vulcan, aiming to revolutionize warehouse automation through advanced tactile sensing technologies. Introduced at the “Delivering the Future” event in Dortmund, Germany, Vulcan is a vital component of Amazon’s broader Sequoia system. It promises to enhance order processing and efficiency within fulfillment centers. According to reports, Sequoia significantly boosts speed by up to 75% and reduces order handling time by 25%, marking a substantial leap in Amazon’s logistics capabilities. As automation in the logistics sector advances rapidly, Vulcan’s introduction signals a transformative moment in how inventory management is approached, blending technological innovation with practical workplace needs.

Vulcan’s Role in Fulfillment Centers

Vulcan’s primary function is to optimize inventory management, specifically targeting areas that pose ergonomic challenges to human workers. Before Vulcan’s deployment, accessing items on the highest shelves often required ladders, while retrieving from the lowest shelves necessitated awkward bending. Such tasks not only slowed down operations but also introduced potential safety hazards for employees. Amazon’s move to automate these tasks not only speeds up workflows but also aims to create a safer and more ergonomically friendly work environment for its personnel. By eliminating these physically demanding duties, Vulcan enables a smoother, more efficient handling of inventory, which contributes to overall productivity within the fulfillment centers.

In addition to workplace safety improvements, Vulcan plays a crucial role in enhancing operational efficiency. The robotic system swiftly and accurately manages inventory at varying heights, thereby reducing the time and effort required to complete these tasks manually. This automated approach is designed not only to meet the demands of high-volume fulfillment but also to cater to the intricate process of sorting and stowing items accurately. By focusing on these tasks, Vulcan relieves human workers from repetitive strain and allows them to engage in roles that require more cognitive input, ultimately supporting a more dynamic workforce in Amazon’s advanced fulfillment operations.

Technical Features of Vulcan

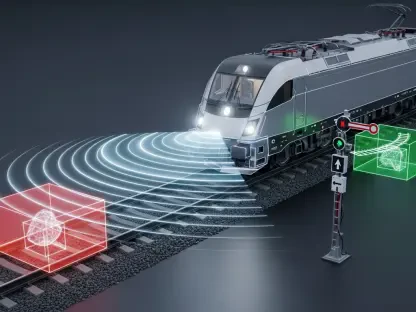

Vulcan relies on an array of technical innovations to achieve its efficiency and precision in handling diverse inventory tasks. The system’s unique “end of arm tooling” bears resemblance to a ruler affixed to a hair straightener, a design that incorporates sophisticated force feedback sensors. These sensors provide Vulcan the essential ability to sense contact, enabling precise force modulation, thus preventing damage to delicate items. During the stowing process, Vulcan employs paddle-like grippers equipped with minute conveyor belts, which automatically adjust their grip to accommodate the size of each item. This dynamic adaptability ensures secure placement without compromising the item’s integrity.

For the picking process, Vulcan utilizes a specialized arm that integrates a camera and suction cup mechanism. The camera’s role is crucial as it meticulously identifies the target item and determines the ideal location for gripping. This technology ensures that Vulcan retrieves only the desired product, minimizing the risk of unintended co-extraction of nearby items. Such technical precision is not just an engineering marvel but a real-world solution to handling the extensive inventory challenges typical of Amazon’s fulfillment centers. By refining the picking and stowing processes, Vulcan addresses the complexities of modern warehousing with a level of accuracy and care that surpasses traditional methods.

Sensory Capabilities Beyond Traditional Robots

In contrast to traditional industrial robots, which often lacked sensory perception, Vulcan stands out with its advanced sensory capabilities. Traditional robots typically either stopped suddenly or continued blindly when encountering unforeseen contact, which sometimes led to mishandling of items. Vulcan, however, is designed to feel its surroundings, allowing for a nuanced interaction with its environment. This sensory awareness transforms how the robot navigates tasks, offering functionalities that were once out of reach for past iterations of Amazon robots. Vulcan can detect items that are difficult to manage autonomously, and when required, it can request assistance from human workers, ensuring that efficiency is maintained without sacrificing precision.

This sensory advancement in robotic technology enables Vulcan to execute tasks once considered too delicate or complex for machines. Through its capability to feel and react like a human, the system offers a new dimension of operational efficiency and accuracy that aligns with Amazon’s ambitious automation goals. By mimicking human sensory responses, Vulcan integrates seamlessly into the existing workflow, providing robust support without the need for constant human supervision. This evolution in robotic interaction marks a significant milestone in the push towards a more automated yet human-centered industrial environment, where machines not only perform tasks but do so with an understanding of the intricacies involved.

Human-Robot Collaboration

Amazon’s introduction of Vulcan underscores its emphasis on human-robot collaboration, asserting that these robotic innovations are designed not to replace human workers but to amplify their capabilities. The interaction between robots and humans is vital, as human oversight remains central to addressing complex issues such as damage assessment and safety evaluations that require human intuition. Amazon’s leadership believes that the intelligence of Vulcan is meant to complement human work, allowing humans to focus on supervisory tasks and decision-making abilities that machines cannot replicate. Importantly, newer robotic generations, including Vulcan, have the capability to solicit guidance, aiding a collaborative learning process that mirrors human development.

The Vulcan system epitomizes an advanced learning mechanism, where the AI is trained to adapt and learn from its failures similarly to humans. Such a capacity allows Vulcan to continuously improve, adapting to new challenges and integrating these learning experiences into its operations. This innovative approach to robotics is part of Amazon’s broader strategy of fostering a harmonious relationship between human oversight and autonomous robot tasks. By enabling robots like Vulcan to learn and evolve alongside human employees, Amazon is working to create an ever-improving and increasingly efficient work environment that remains dependent on human critical thinking and innovation.

Strategic AI and Robotics Integration

Vulcan’s development represents a significant step in Amazon’s overarching strategy to integrate sophisticated AI and robotics into its logistics operations. Vulcan’s technology builds on foundational systems like Sparrow, Cardinal, and Titan, all of which contribute to Amazon’s pursuit of operational excellence. Moreover, Amazon’s strategic collaborations, such as incorporating AI models from Covariant AI, enhance the intelligence and effectiveness of its robotic solutions. This comprehensive approach not only strengthens Amazon’s technological infrastructure but also positions the company at the forefront of the logistics industry’s shift towards advanced automation.

As part of its strategic objectives, Amazon is investing in startups and initiatives that push the boundaries in robotics and AI fields. The company’s Industrial Innovation Fund plays a pivotal role in supporting these efforts, focusing on investing in technologies that align with their vision of automating logistics processes efficiently. By fostering these partnerships and investments, Amazon aims to create a synergy between AI and robotics, potentially transforming the landscape of logistics and fulfillment. This integration is pivotal for the company’s pursuit of streamlining operations, reducing costs, and enhancing overall service quality, a testament to its commitment to innovation.

Investment in European Automation

Amazon’s investment in European logistics automation reflects its commitment to leveraging advanced technology for operational superiority, with total investments in this area exceeding €1.7 billion over recent years. This substantial financial backing underscores Amazon’s strategy to deploy an array of state-of-the-art robotic and AI systems across Europe, enhancing infrastructure designed to meet the evolving demands of modern commerce. The Dortmund fulfillment center, which alone represents an investment of over €400 million, serves as a key hub for integrating innovations like Vulcan and other advanced systems, solidifying Amazon’s presence and influence in the European market.

The Sequoia system employed in Dortmund, seamlessly harmonizing Vulcan with other innovations such as Sparrow II for tote picking and Cardinal for package sorting, epitomizes Amazon’s approach to utilizing synergistic solutions to streamline its logistics chain. Beyond these systems, Amazon is also adopting automated packaging machines that craft custom-fit boxes aimed at minimizing waste, further exemplifying the company’s commitment to sustainability in its operations. These strategic implementations are geared toward enhancing efficiency while simultaneously maintaining environmental consciousness, setting a benchmark for future warehouse automation projects across the globe.

Workforce Implications and Upskilling Initiative

The launch of Vulcan has sparked an ongoing dialogue about the implications of automation on workforce dynamics within Amazon’s operations. While Vulcan presents significant ergonomic benefits and efficiencies, its introduction has also raised concerns regarding potential impacts on job security. However, Amazon emphasizes its commitment to workforce development through initiatives like the Upskilling 2025 program. This extensive effort aims to retrain 300,000 employees by the year-end, with a substantial investment exceeding $1.2 billion. Such programs are designed to equip employees with new skills that complement the technological advancements within Amazon’s ecosystem, preparing them for emerging roles and responsibilities.

Many Amazon workers have reported positive experiences with Vulcan, acknowledging how the technology has allowed them to transition into more technically sophisticated roles. These opportunities for skill enhancement are crucial as the logistics industry becomes increasingly automated. While there are understandable concerns about automation-induced job losses, Amazon’s proactive approach to workforce upskilling serves as a buffer, ensuring that its employees remain valuable assets capable of thriving alongside technological advancements. This dual focus on technological efficiency and human capital development is essential in navigating the evolving industrial landscape that automation continues to reshape.

Broader Industry Developments

Amazon has unveiled Vulcan, a pioneering robotic system designed to transform warehouse automation with cutting-edge tactile sensing technology. Introduced at the “Delivering the Future” event in Dortmund, Germany, Vulcan is a key component of Amazon’s expansive Sequoia system, which aims to significantly improve order processing and operational efficiency in fulfillment centers. Reports suggest that the Sequoia system can accelerate order processing speed by up to 75% and reduce handling time by 25%, representing a considerable advancement in Amazon’s logistics capabilities. As the logistics sector increasingly embraces automation, Vulcan marks a pivotal shift in inventory management approaches, marrying technological advancements with real-world workplace demands. Companies are inevitably on the brink of change, as such innovations highlight the ongoing journey towards streamlined operations and heightened capabilities, further strengthening Amazon’s position in the competitive environment of modern logistics.