I’m thrilled to sit down with Rohit Laila, a veteran in the logistics industry with decades of experience spanning supply chain and delivery. Rohit’s deep passion for technology and innovation has positioned him as a thought leader in transforming how warehouses and supply chains operate. In this conversation, we dive into the exciting world of warehouse automation, exploring how cutting-edge AI and robotics are reshaping the industry, the significance of major financial backing, global expansion strategies, and the future of intelligent systems that turn data into action.

How did you first get involved in the intersection of logistics and technology, and what excites you most about the innovations happening in this space today?

My journey in logistics started with a fascination for how goods move across the world, and over the years, I saw technology as the key to solving some of the biggest inefficiencies in the industry. What excites me now is how rapidly we’re moving toward autonomous systems and AI-driven solutions. The ability to have real-time visibility and actionable insights in warehouses is a game-changer—it’s not just about tracking inventory anymore, but about predicting and optimizing every step of the supply chain.

Can you walk us through how AI and robotics are transforming warehouse operations, especially in terms of efficiency and visibility?

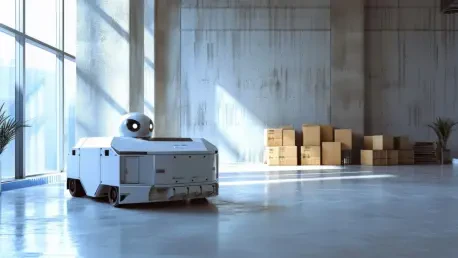

Absolutely. AI and robotics are revolutionizing warehouses by automating repetitive tasks and providing data that humans simply can’t process at scale. Robots can scan and map entire facilities in real time, collecting data on inventory locations, stock levels, and even operational bottlenecks. AI then analyzes this data to offer insights, helping managers make decisions faster—whether it’s rerouting a picker to avoid congestion or identifying stock discrepancies before they become problems. This cuts down on errors and boosts efficiency dramatically.

What does a major funding milestone, like a recent $165 million raise, signify for a company in the logistics tech space, and how does it impact future growth?

A funding round of that size signals strong confidence from investors in the company’s vision and its ability to deliver results. It’s a validation of the value being created for customers. For growth, it means the company can accelerate its plans—whether that’s scaling up technology development, hiring top talent, or expanding into new markets. It’s like getting a turbo boost to turn ambitious ideas into reality much faster than before.

When it comes to expanding globally, what factors do you think are critical for success in diverse regions like Europe, North America, and Asia-Pacific?

Global expansion is tricky but exciting. The key factors are understanding local market needs and regulations, building strong partnerships, and ensuring your technology can adapt to different operational environments. For instance, warehouse layouts and labor practices vary widely between regions. You also need a physical presence, like setting up a headquarters in a strategic location, to build trust and provide hands-on support. It’s about balancing standardization of your tech with customization for local challenges.

How do autonomous robots contribute to gathering live data in warehouses, and what kind of impact does this have on day-to-day operations?

Autonomous robots are like tireless scouts in a warehouse. They navigate aisles, scan barcodes, and capture data on everything from inventory placement to space utilization, all in real time. This live data feed means managers don’t have to wait for manual counts or outdated reports—they can see exactly what’s happening as it happens. The impact is huge: faster decision-making, reduced downtime, and the ability to spot issues like misplaced items instantly, which keeps operations running smoothly.

Can you share a story about how these technologies have made a tangible difference for a major logistics player or manufacturer?

I’ve seen firsthand how transformative this can be. For a large logistics provider, implementing AI-driven visibility tools and autonomous robots cut their inventory audit time from days to hours. They were dealing with constant discrepancies that slowed down their shipping schedules. With real-time data, they could pinpoint errors immediately and reallocate resources on the fly. It not only saved time but also improved their customer satisfaction because deliveries were more reliable.

What are some of the biggest challenges or bottlenecks in warehouse transformation that technology is still working to overcome?

One major challenge is integrating new tech with legacy systems—many warehouses still run on outdated software that doesn’t play well with modern solutions. Another is scalability; a pilot might work great in one facility, but rolling it out across dozens of locations with different setups is tough. Then there’s the human factor—training staff to trust and use these systems takes time. Technology is getting better at addressing these, but it’s still a work in progress.

How do you envision the concept of shifting warehouses from ‘systems of record’ to ‘systems of action’ changing the future of supply chains?

The shift is all about moving from passively logging data to actively using it to drive decisions. A ‘system of record’ just tells you what happened—inventory levels, past shipments, etc. A ‘system of action’ uses that data, often with AI, to predict issues and suggest solutions in real time, like rerouting a robot to avoid a jam or flagging low stock before it’s a problem. This proactive approach can make supply chains more resilient, cutting delays and costs while adapting to disruptions instantly.

Looking ahead, what is your forecast for the role of AI and robotics in the evolution of global supply chains over the next decade?

I believe AI and robotics will become the backbone of global supply chains within the next ten years. We’ll see fully autonomous warehouses where robots handle most physical tasks, and AI orchestrates everything from inventory to delivery schedules. The focus will shift to predictive analytics—anticipating demand spikes or disruptions before they happen. This will create supply chains that are not just efficient but also adaptive, able to pivot instantly in a crisis. It’s an exciting future, and we’re just at the beginning of this transformation.