The intricate web of global commerce, once celebrated for its efficiency, has revealed a profound vulnerability in recent years, demonstrating that a single disruption can trigger a cascade of failures with far-reaching consequences for businesses and consumers alike. The traditional, linear model of supply chain management, optimized purely for cost and speed, is no longer sufficient in an era defined by volatility. To navigate this new landscape, organizations are compelled to reimagine their logistical frameworks, transforming them from rigid, cost-centric operations into dynamic, intelligent systems. This evolution demands a fundamental shift toward building supply chains that are not only resilient enough to withstand shocks but also agile enough to capitalize on change. The core challenge lies in integrating advanced technology, fostering strategic partnerships, and cultivating a culture of continuous adaptation, thereby turning a potential liability into a powerful strategic advantage that drives both stability and growth.

The New Imperatives for Supply Chain Modernization

A critical first step in this modernization journey is the deliberate fortification of resilience through comprehensive operational visibility. This extends far beyond tracking shipments; it involves harnessing real-time analytics to create a transparent, end-to-end view of the entire supply chain. By integrating data streams from suppliers, manufacturers, logistics partners, and even end-users, organizations can move from a reactive to a proactive stance. Advanced analytical tools allow for the identification of potential bottlenecks, demand fluctuations, and geopolitical risks before they escalate into full-blown crises. This complete visibility enables decision-makers to conduct sophisticated “what-if” scenario planning, stress-testing the supply chain against various potential disruptions. Consequently, companies can develop more robust contingency plans, diversify their sourcing strategies intelligently, and ensure that their operations can absorb and recover from unexpected events with minimal impact on service levels and profitability.

Parallel to enhancing visibility, the imperative to attract and retain top talent has become a central pillar of supply chain strategy. The operational environment is increasingly complex, requiring a workforce skilled in data analytics, automation, and strategic thinking. To secure this talent, leading organizations are focusing intently on improving the overall worker experience. This includes investing in ergonomic technologies, providing continuous upskilling and professional development opportunities, and creating a safer, more engaging work environment. A motivated and skilled workforce is not merely a cost but a significant driver of productivity and innovation. When employees feel valued and are equipped with the right tools and training, they are more likely to identify process inefficiencies and contribute to a culture of continuous improvement, which is essential for maintaining a competitive edge in a rapidly changing market.

The Technological Vanguard of Agility

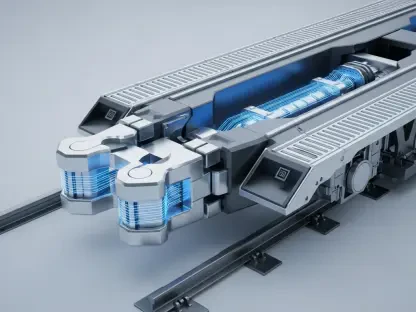

The integration of advanced technology, particularly automation and deeper system integration, serves as the engine driving the transformation toward a more agile supply chain. The focus is shifting toward creating interconnected ecosystems where information flows seamlessly between disparate systems, from enterprise resource planning (ERP) to warehouse management (WMS) and transportation logistics. This deep integration is the foundation upon which powerful automation can be built. For instance, Generative AI is being deployed to automate complex processes like guided buying, which helps employees make compliant and cost-effective procurement decisions without extensive manual oversight. AI-powered platforms can also analyze vast datasets to identify patterns and anomalies, providing insights that would be impossible for human analysts to uncover. This technological fusion allows organizations to respond to market shifts with unprecedented speed and precision.

Building on this foundation, nimbleness is achieved by leveraging AI to eliminate administrative friction and accelerate data analysis. The goal is to free up human capital from repetitive, low-value tasks so they can focus on strategic initiatives. AI algorithms can now automate supplier vetting, conduct real-time fraud detection, and manage risk assessments with a level of speed and accuracy that far surpasses manual methods. This capability is crucial for quickly onboarding new suppliers to mitigate single-source vulnerabilities, a concept known as building “supplier redundancy.” By utilizing AI to rapidly analyze and qualify potential partners from a vast network, companies can build a more diversified and therefore more resilient supply base. This nimbleness ensures that when a primary supplier faces a disruption, the supply chain can pivot to an alternative source almost instantaneously, maintaining continuity and protecting the flow of goods.

A Blueprint for a Future-Proof Operation

The strategic pivot toward sustainability and achieving Net Zero emissions has become an inseparable component of a resilient supply chain, proving to be beneficial for both environmental responsibility and long-term affordability. Forward-thinking companies are discovering that sustainable practices often lead to greater operational efficiencies. For instance, optimizing transportation routes to reduce fuel consumption also lowers costs and carbon footprints. Sourcing from local and diverse suppliers not only supports community economies and reduces transportation distances but also mitigates the risks associated with long, complex international supply lines. By integrating sustainability goals into core procurement and logistics strategies, organizations can enhance their brand reputation, comply with evolving regulations, and uncover new efficiencies that contribute directly to the bottom line, framing sustainability not as a cost center but as a value driver.

Ultimately, the journey toward a more resilient and agile supply chain was defined by a clear directive to embrace new technologies and build security through strategic, flexible sourcing. The leaders in this space interrogated their data with sophisticated AI to uncover novel solutions and anticipate challenges before they emerged. Through a commitment to continuous adaptation, they transformed their supply chains from a mere logistical necessity into a strategic differentiator. This evolution required not just technological investment but a cultural shift toward proactive risk management and strategic collaboration. By doing so, they not only weathered the storms of global uncertainty but also positioned themselves to thrive in a constantly changing world, demonstrating that a well-managed supply chain was one of the most powerful competitive advantages a modern enterprise could possess.