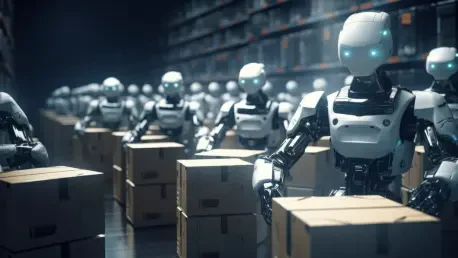

The relentless rhythm of packages moving through a logistics hub is about to encounter a significant technological shift, underscored by a major new investment from one of the industry’s giants. United Parcel Service is committing $120 million to acquire approximately 400 truck-unloading robots, a move that signals a profound evolution in how global supply chains operate. This initiative is more than just a capital expenditure; it represents a critical juncture where automation and human labor are being purposefully integrated on an unprecedented scale.

A Glimpse into the Future of the UPS Loading Dock

UPS is setting the stage for a dramatic operational overhaul with its acquisition of robots from Pickle Robot Co. The deployment, scheduled to begin in the latter half of 2026, aims to introduce a fleet of automated systems designed to handle one of the most physically demanding jobs in any warehouse. This investment is a key component of a much larger vision.

The acquisition is part of the company’s ambitious $9 billion automation strategy, which is projected to generate $3 billion in cost savings by 2028. By targeting the unloading process, UPS is addressing a critical bottleneck, aiming to streamline operations from the moment a truck arrives at the dock. This strategic move is calculated to enhance efficiency and build a more resilient supply chain.

The Driving Forces Behind the Automation Push

The primary motivation behind this technological leap is the pursuit of speed and cost reduction. Unloading trucks is a repetitive and strenuous task that can slow down the entire sorting process. Automating this function is expected to accelerate package handling significantly, allowing goods to move through the facility faster.

This trend extends far beyond a single company. The logistics industry as a whole is turning toward robotics to solve persistent challenges, including labor shortages, the need for improved worker safety, and the difficulty of managing unpredictable consumer demand. Automation provides a scalable solution that can operate consistently, helping companies adapt to market fluctuations more effectively.

Unpacking the Technology of the Robotic Unloader

The technology at the heart of this transformation is sophisticated yet practical. The Pickle Robot unloaders utilize a combination of artificial intelligence, advanced sensors, and high-resolution cameras to identify and handle packages of various shapes and sizes, up to 50 pounds. This AI-driven perception allows the robots to work with the disorganized environment typically found inside a packed trailer.

A key advantage of these machines is their ability to integrate into existing infrastructure without requiring major facility redesigns. A single robot can unload a standard truck in approximately two hours, a pace that complements human-led teams. This design philosophy emphasizes augmenting current operations rather than completely replacing them, making the technology more accessible for widespread adoption.

A Strategy of Collaboration Over Replacement

UPS has been clear that its goal is not to eliminate jobs but to enhance them. The official stance is that these robots are designed to assist human workers by taking over the most physically taxing and repetitive tasks. This approach reflects a broader industry shift toward collaborative robots, or “cobots,” that work alongside people.

By automating the heavy lifting, the company plans to reassign employees to other, less strenuous roles within the warehouse. This strategy suggests a future where human workers are responsible for tasks requiring more complex problem-solving, oversight, and dexterity, while robots handle the monotonous physical labor.

Redefining the Role of the Human Employee

The integration of advanced robotics marked a turning point for the warehouse workforce. Rather than signaling an end to human labor, this development redefined its very nature. The focus shifted from manual, repetitive actions to roles centered on technology management, system oversight, and quality control. This evolution underscored that while machines could handle the strain, human intellect and adaptability remained indispensable to navigating the complexities of a modern logistics network. The warehouse job of the future became less about lifting boxes and more about orchestrating the technology that did.