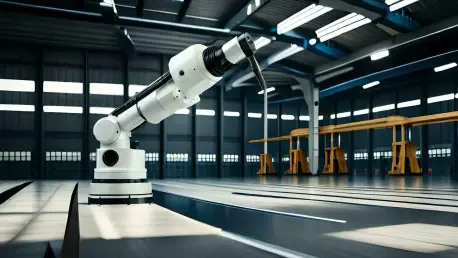

The advent of robotics and automation is revolutionizing warehousing, marking a significant shift in how goods are stored, managed, and distributed. As companies strive to meet increasing consumer demands and navigate complex supply chains, understanding this trend becomes crucial for maintaining a competitive edge in the logistics industry. This article delves into the current landscape and adoption of robotics, expert opinions, and the promising future of these technologies in warehousing.

Current Landscape and Adoption of Robotics in Warehousing

Growth Trends and Market Insights

Robotics in warehousing has experienced substantial growth, underscored by impressive global adoption rates. According to various industry reports, the integration of robotics is projected to grow at a compound annual growth rate (CAGR) of 18.2% over the next few years. This trajectory is fueled by the rising demand for efficiency and accuracy in warehouse operations. Industry-leading firms such as DHL and Walmart are at the forefront, exemplifying successful robotic integration and paving the way for others.

Real-World Applications and Case Studies

Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) are spearheading innovations within the sector. Companies employing these technologies have reported marked improvements in operational efficiency and cost savings. For instance, DHL has incorporated robotics to streamline their supply chain processes, and Walmart has employed various robotic solutions to optimize its inventory management. These case studies highlight the effectiveness of robotic applications in real-world settings, showcasing their potential to reshape warehousing.

Expert Opinions and Industry Insights

Insight from industry leaders and experts suggests that while the transition to robotics offers numerous benefits, it is not without challenges. Experts echo a shared sentiment: the logistics industry must navigate technical hindrances, such as robotic system compatibility and integration with existing operations, as well as manage workforce shifts due to increased automation. Proposed solutions include robust training programs and scalable technology strategies to ease this transition.

Industry experts also emphasize the importance of scalability and flexibility in adopting these technologies. They forecast continued advancements, such as more refined machine-learning capabilities and better data analysis, which could address current inefficiencies. By preparing for and adapting to these innovations, companies can harness the full potential of robotics to drive substantial gains in productivity and precision.

Future Outlook for Robotics and Automation in Warehousing

Technological advancements in robotics hold promise for transforming warehouse operations even further. Future developments may introduce more sophisticated AI-driven robots that enhance decision-making and automation efficiency. Despite these benefits, potential challenges remain. These include workforce displacement, requiring firms to consider ethical implications and possible retraining programs for existing employees.

The industry may face ethical dilemmas and workforce challenges as automation takes on more roles traditionally held by humans. Companies will need to strategize on workforce management and ethical considerations, ensuring that automation benefits are balanced against potential socioeconomic impacts. Addressing these challenges thoughtfully could pave the way for a more informed and prepared transition into an automated future.

Conclusion and Implications for the Industry

Robotics and automation offer transformative potential for the warehousing sector, poised to redefine operational efficiencies and drive growth. Adapting to this trend is imperative for industry stakeholders who wish to remain competitive and relevant. By embracing the changes robotics bring to warehousing, companies could position themselves to capitalize on emerging opportunities and address the challenges that arise. Preparing for these shifts will require strategic planning and a willingness to invest in technologies that redefine workplace dynamics and productivity, ensuring a robust foundation for the industry’s future.