In today’s rapidly evolving global market, managing long product lifecycles and supply chain challenges is crucial for industries such as aerospace, defense, automotive, and medical sectors. These industries rely on products with production lifespans exceeding five years, necessitating robust strategies to ensure component availability and product support over extended durations. This article delves into the essential strategies and practices for developing resilient, adaptable, and cost-optimized supply chains for long-lifecycle products (LLCPs).

Proactive Management of Component Specifications and Obsolescence

Importance of Component Specifications

Maintaining a steady and reliable supply of components is vital for LLCPs. Proactive management of component specifications helps mitigate the risks associated with supply shortages and the need for redesigns. By systematically managing these specifications, companies can forecast potential obsolescence and address it before it impacts production. Given the extended production lifespans of products in sectors like aerospace and defense, uninterrupted availability of components ensures that these products remain functional and supportable over their entire lifecycle. This level of planning ensures that even as technology evolves, the essential components for LLCPs remain accessible and work seamlessly within existing systems.

Being proactive also involves extensive testing and validation of alternative parts that can seamlessly substitute original components without affecting performance. It requires forecasting potential future shortages and working closely with suppliers to secure reliable sources. Companies can develop relationships with multiple suppliers to ensure that single-source risks are minimized. This holistic approach ensures that LLCPs do not face sudden production or operational interruptions due to component shortages or unexpected obsolescence.

Addressing Obsolescence Challenges

In sectors where continuous redesign is financially and logistically prohibitive, managing obsolescence becomes critical. Benchmark’s approach to forecasting potential obsolescence involves sophisticated modeling and market analysis to predict when a component might become obsolete. By identifying these risks early, Benchmark implements strategies to mitigate cost implications and operational disruptions, ensuring that LLCPs remain viable and cost-effective throughout their lifecycle. This kind of forward-thinking strategy allows businesses not only to plan for known obsolescence but also to develop contingencies for unforeseen component phase-outs or end-of-life scenarios.

Addressing obsolescence proactively often includes measures such as lifetime buys, where companies purchase a last-time buy stock of a component before it is discontinued. These components are stored securely and carefully to prevent degradation over time. Despite the upfront cost, this practice secures a stable supply of critical parts. Another approach is leveraging automated systems to keep track of component status, updates, and potential phase-out notifications from suppliers. By doing so, companies can preemptively manage their inventories and decision-making processes to account for gradual obsolescence or sudden supply chain shocks.

Adapting to Global Disruptions and Technological Advances

Impact of Global Disruptions

Recent global challenges, such as semiconductor shortages during the pandemic, have exposed vulnerabilities within component supply chains. These disruptions have critically impacted industries reliant on semiconductors, leading to production delays, increased prices, and exacerbated global inflation. Understanding these impacts is essential for developing resilient supply chains. For instance, the automotive industry faced significant setbacks as factories halted production lines while waiting for key electronic components, ultimately increasing vehicle prices and contributing to broader economic disturbances. By learning from these disruptions, companies can refine their supply chain strategies to better withstand future shocks.

Organizations are increasingly employing a dual sourcing strategy to mitigate risks, where key components are sourced from multiple vendors situated in different geographical regions. This not only spreads the risk but also leverages regional strengths in terms of quicker response times and localized supply chain management. Additionally, building strategic partnerships with suppliers ensures a more collaborative approach where both parties work towards mutual benefit. This collaborative effort can include shared forecasting data, joint risk management frameworks, and co-investment in securing long-term supply resilience.

Technological Advances and Supply Chain Adaptation

Technological advancements present both opportunities and challenges for supply chains. A structured supply chain requires meticulous planning and preparation to adapt to these changes. By integrating new technologies and practices, companies can enhance their supply chain resilience and maintain product quality and performance. This includes adopting digital twin technologies that create virtual replicas of physical supply chains, allowing managers to simulate different scenarios and foresee potential bottlenecks. These digital tools aid in optimizing operations, improving lead times, and reducing costs through more efficient use of resources and intelligent planning systems.

Incorporating advanced technologies such as blockchain for supply chain transparency and traceability further strengthens the reliability of supply networks. Blockchain can provide secure and real-time verification of every transaction within the supply chain, reducing fraud and ensuring authenticity. Moreover, artificial intelligence (AI) and machine learning (ML) algorithms can predict demand patterns, optimize logistics routes, and enhance inventory management, all of which are critical for adapting to rapid technological shifts. By leveraging these tools, companies can build more agile and robust supply chains capable of responding swiftly to technological advancements and unexpected market changes.

Designing Resilient Supply Chains

Sustainability in Supply Chain Design

Manufacturers today are increasingly mindful of the environmental impact of their supply chains. Sustainable designs, including the use of biodegradable and recyclable materials, are becoming a priority. This section explores how manufacturers can integrate sustainability into their supply chain strategies to reduce environmental impact. By opting for environmentally friendly materials and production processes, manufacturers not only contribute to global sustainability goals but also appeal to the growing consumer demand for greener products. This commitment to sustainability encompasses the entire lifecycle of the product, from design and material sourcing to manufacturing, distribution, and end-of-life disposal.

Implementing circular economy principles within the supply chain, where materials are reused, remanufactured, or recycled, plays a significant role in reducing waste and promoting sustainability. This holistic approach encourages the use of renewable resources and minimizes reliance on non-renewable materials. For example, in the electronics industry, manufacturers are increasingly designing products that are easier to disassemble and recycle. Sustainable supply chain practices also involve reducing energy consumption, optimizing transportation logistics to cut down on carbon emissions, and selecting suppliers who adhere to stringent environmental standards.

Cybersecurity Considerations

Maintaining a robust supply chain for LLCPs also necessitates vigilance against cybersecurity threats. Ensuring the secure management of product design and manufacturing data is crucial. This includes implementing strong cybersecurity measures and educating stakeholders on the latest risks to safeguard product information. As supply chains become more interconnected and digital, the risk of cyberattacks increases. Manufacturers must implement advanced cybersecurity protocols such as encryption, multi-factor authentication, and continuous monitoring to protect sensitive data from breaches and unauthorized access.

Cybersecurity also extends to ensuring the integrity and authenticity of components sourced from various suppliers. Counterfeit components pose a significant risk to the quality and reliability of LLCPs. Companies must establish rigorous supplier vetting processes and employ technologies like blockchain to track and verify the provenance of every component. Educating all stakeholders, from engineers to supply chain managers, on the importance of cybersecurity and the latest threats is essential for maintaining the integrity of the supply chain. Regular training and drills can prepare the workforce to respond swiftly and effectively to potential cyber incidents, thereby preserving the security and reliability of the supply chain infrastructure.

Automation and Advanced Manufacturing Techniques

Role of Automation in Supply Chains

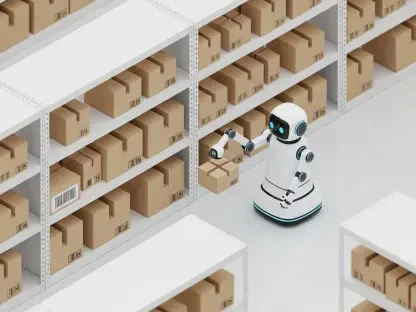

Automation and advanced manufacturing techniques play a significant role in building future-ready supply chains. Techniques such as computerized pick-and-place machines and automated assembly of surface mount technology (SMT) components expand potential component options. Automation helps in enhancing precision, reducing human error, and accelerating production rates. Automated systems can handle complex assembly tasks with higher consistency than manual labor, leading to improved product quality and reduced manufacturing time. This efficiency is particularly beneficial for LLCPs, which often require customized or semi-custom components that demand meticulous assembly.

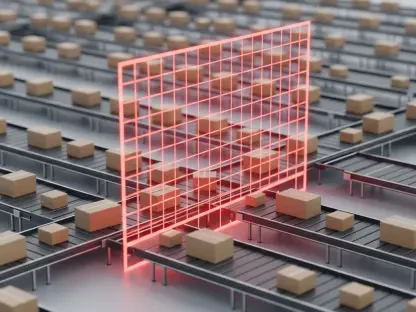

The integration of automation extends to warehouse management systems (WMS) and enterprise resource planning (ERP) systems that streamline the overall supply chain process. Automated guided vehicles (AGVs) and robotic process automation (RPA) help optimize material handling, inventory management, and order fulfillment processes. These technologies reduce operational costs and improve supply chain agility. By leveraging automation, companies can also improve traceability and monitoring of each production phase, ensuring strict adherence to quality standards and regulatory compliances, which is paramount in industries such as aerospace and medical devices.

Benefits of Advanced Manufacturing

The ability to design multilayer printed-circuit boards (PCBs) facilitates the creation of more flexible and sustainable BOMs. This is vital for reducing size, weight, and power consumption in sectors like aerospace, defense, automotive, and healthcare. Advanced manufacturing techniques enable the production of intricate and high-performance components that are essential for modern, compact, and energy-efficient devices. These advanced techniques also include additive manufacturing, or 3D printing, which allows for rapid prototyping and on-demand production of complex parts, further enhancing flexibility and reducing lead times.

An automated and miniaturized supply chain ensures that LLCPs meet specific application demands while maintaining product quality and performance. Advanced materials, such as lightweight composites and high-temperature resistant alloys, prolong the lifecycle and enhance the performance of LLCPs. By employing advanced manufacturing, companies can achieve significant cost savings through material efficiency and reduced waste. This approach aligns with sustainability goals by minimizing the environmental footprint of production processes. Complex geometries and customized solutions become more feasible, allowing manufacturers to respond promptly to market demands and technological innovations.

Coordinating Product Lead Times and Cost Targets

Collaboration with Customers

A structured and well-managed supply chain must coordinate product lead times with customers and proactively meet cost targets over time. From the design stage, Benchmark’s engineers collaborate with customers to establish optimized supply chains. This section explores the importance of thoughtful analysis and planning in achieving stable and scalable supply chains. By engaging customers early in the design and development process, companies can ensure their supply chains are tailored to meet specific requirements and expectations. This collaboration fosters transparency, aligns production schedules with market demands, and enhances customer satisfaction.

Effective coordination involves continuous communication and feedback loops between manufacturers and customers. Agile methodologies can be applied to adapt plans swiftly based on changing customer needs or market conditions. Joint planning sessions and regular reviews help align production timelines, optimize inventory levels, and manage costs more effectively. Collaboration tools and platforms facilitate seamless interaction, ensuring that all stakeholders are informed and engaged throughout the lifecycle of the product. This integrated approach not only enhances supply chain efficiency but also builds stronger, more resilient relationships with customers.

Mitigating Production Disruptions

To mitigate production disruptions, modest buffer stocks or safety production purchases can be maintained. Benchmark’s Design for Supply Chain (DFSc) strategy ensures an adequate component supply even during unforeseen production shortages or unexpected demand spikes. This comprehensive approach integrates intelligent supply chain management with engineering design, test development, and manufacturing serviceability. Maintaining buffer stocks provides a safety net, allowing production to continue smoothly when supply chain hiccups occur. However, the challenge lies in optimizing these safety stocks to avoid excess inventory costs while ensuring enough reserve to cover potential disruptions.

Intelligent supply chain management systems leverage real-time data and predictive analytics to anticipate demand fluctuations and adjust procurement and production schedules accordingly. These systems provide visibility into the entire supply chain, enabling proactive management of potential issues before they escalate into significant disruptions. Strategies like vendor-managed inventory (VMI) and just-in-time (JIT) inventory can be employed to balance supply and demand efficiently. By aligning production durations with market demands, companies can minimize delays, reduce holding costs, and improve overall responsiveness to customer needs.

Synchronizing Demand, Supply, Production, and Fulfillment

Importance of Close Collaboration

Benchmark’s methodology includes close collaboration with suppliers, customers, and end-users to synchronize demand, supply, production, and fulfillment requirements. This is particularly crucial for products in the aerospace, defense, communications, critical infrastructure, automotive, and medical sectors. Close collaboration ensures that all stakeholders are aligned and working towards common goals, reducing the risk of miscommunications and delays. By fostering a collaborative environment, companies can better anticipate and respond to market changes, optimize resource allocation, and enhance the overall efficiency of the supply chain.

Regular coordination meetings and shared planning tools facilitate timely decision-making and transparency. Establishing long-term partnerships with key suppliers fosters a sense of shared responsibility and encourages investment in mutual growth and innovation. Collaborative forecasting and inventory planning enable better alignment of production schedules with actual market demand, reducing the likelihood of overproduction or stockouts. Additionally, involving customers and end-users in the design and development phases can provide valuable insights, ensuring that the final product meets their needs and expectations.

Data-Driven Planning and Production Systems

In today’s rapidly changing global market, it is essential for industries such as aerospace, defense, automotive, and medical sectors to effectively manage long product lifecycles and supply chain complexities. These sectors depend on products that have production spans of more than five years, which requires robust strategies to ensure the consistent availability of components and support for these extended periods. This article explores vital strategies and best practices for developing resilient, adaptable, and cost-effective supply chains for long-lifecycle products (LLCPs).

Given the extended production timelines, manufacturers in these sectors need to focus on strategic planning to mitigate risks and avoid disruptions to the supply chain. This involves identifying reliable suppliers, ensuring a steady supply of materials, and anticipating potential challenges that may arise over the product’s lifecycle. Additionally, it is important to incorporate flexible planning to adapt to technology advancements and market changes. Implementing these strategies helps maintain efficiency and cost-effectiveness, ultimately leading to sustainable success in managing long-lifecycle products.