The rapid expansion of e-commerce and online fulfillment operations is placing unprecedented pressure on existing warehouse infrastructure, often forcing companies to adapt facilities that were never designed with high-volume logistics in mind. A significant and common challenge arises when a facility has a completely flat floor, lacking the traditional raised docks essential for the efficient loading and unloading of trailers. This structural limitation can create major bottlenecks, slow down operations, and seemingly require extensive, costly, and disruptive construction to remedy by digging a recessed dock pit. This scenario forces logistics managers to choose between compromising on efficiency or committing to a capital-intensive project with significant downtime. However, modern engineering has introduced modular, surface-mounted solutions that effectively circumvent this dilemma, enabling the installation of a high-capacity loading bay directly onto an existing flat floor, transforming a logistical barrier into a functional asset.

Modern Solutions for Flat-Floor Logistics

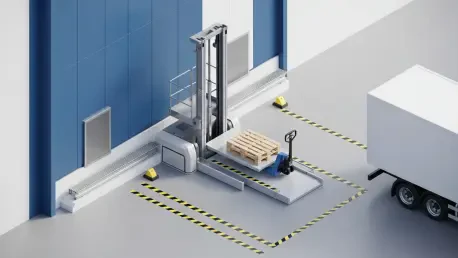

The primary innovation addressing the flat-floor challenge is the Vehicle-to-Ground (V2G) lift, a self-contained system that provides a direct answer without requiring pits or other major groundworks. One notable application was at a major retail distribution center in South Elmsall, where an extension for online fulfillment operations needed a new loading solution in an area with no pre-existing bays. The project involved creating a new opening in the warehouse’s external façade and installing the modular V2G lift directly onto the interior concrete floor slab. This surface-mounted design dramatically reduces installation time and associated costs, minimizing operational disruption. The unit selected for this high-volume environment featured a robust 12-pallet, 5.3-tonne capacity, engineered to handle heavy loads with ease. In a unique design choice, the lift was specified without cladding to maximize the flow of natural light into the warehouse, demonstrating the adaptability of these systems to specific site requirements and operational preferences.

Integrating Safety and Versatility

Beyond the structural advantages, these advanced loading systems delivered a seamless integration of versatility and safety into the facility’s workflow. The V2G lift technology was designed to accommodate the full spectrum of modern logistics vehicles, from small delivery vans to full-sized double-deck trailers, providing true level-access loading for any platform height. This flexibility proved essential for dynamic fulfillment operations where vehicle types can vary daily. Furthermore, the system incorporated multiple safety features to protect personnel and streamline traffic flow. An integrated LED traffic light system clearly communicated when it was safe for vehicles to approach or depart, while a low-gradient loading ramp and a dedicated pedestrian walkway ensured safe movement for both equipment and staff. The installation’s success was marked by its swift delivery and flawless integration, which allowed the company to enhance its logistical capabilities without significant downtime, ultimately providing an efficient and flexible solution that met the demands of a growing e-commerce operation.