The fundamental conversation surrounding warehouse automation has decisively moved beyond simple cost-benefit analyses, now tackling the sophisticated challenges of how to orchestrate complex robotic systems across multiple sites and effectively manage a hybrid workforce of humans and machines. The logistics industry is grappling with an environment where peak-level demand is the new constant, forcing a pivot from asking why warehouses should automate to determining how to build intelligent, flexible, and resilient fulfillment ecosystems. This evolution is not merely an upgrade of existing tools but a complete re-imagining of operational strategy. The central theme for the modern warehouse is the transition from a collection of siloed technologies into a deeply integrated and adaptive network. Industry consensus points toward a future defined by a shift from reactive problem-solving to proactive, predictive management, a transformation driven by the convergence of powerful AI, the expansion of robotics into every corner of the warehouse, and a new strategic emphasis on flexibility, sustainability, and network-wide coordination as the undisputed pillars of a successful fulfillment operation.

The Rise of Intelligent, Predictive Orchestration

From Reactive to Predictive Management

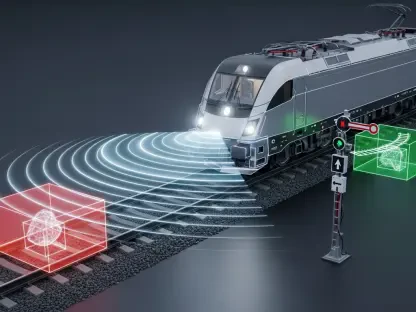

Warehouse orchestration has evolved far beyond its original function of providing real-time visibility into operations, now serving as a predictive engine powered by advanced Artificial Intelligence. Instead of merely reacting to bottlenecks and congestion after they have already begun to slow down productivity, these sophisticated systems use vast historical and real-time datasets to forecast potential issues before they occur. This foresight allows for proactive, automated adjustments that maintain a continuous and uninterrupted flow of goods. For instance, an AI-driven orchestration platform can anticipate a surge in orders in a specific zone and automatically shift labor capacity, both human and robotic, from less busy areas to prevent a backlog. This capability extends beyond a single facility, enabling the system to balance workloads across an entire network of fulfillment centers, ensuring that no single node becomes overwhelmed while others remain underutilized. This marks a critical shift from monitoring to strategic, preemptive intervention.

The practice of leveraging data to inform operational decisions has become both universal and proactive, establishing a new standard where intelligent data design precedes any physical implementation. Warehouse planners now utilize AI-driven modeling and digital twin simulations to design, test, and validate optimal pick paths, zone layouts, and workflow timing in a virtual environment before a single robot is deployed on the floor. This data-first approach involves using onboarding information such as SKU profiles and historical order patterns to pre-design workflows that are efficient from day one. The subsequent step in this evolution integrates predictive analytics that empower warehouse layouts and processes to reconfigure themselves automatically in response to real-time shifts in demand, inventory levels, and product mix. In this paradigm, data is no longer a retrospective report card used for monthly reviews but has become the fundamental, dynamic blueprint for every operational decision, guiding the warehouse’s physical and digital infrastructure in lockstep with market demands.

AI as the Operational Backbone

Artificial Intelligence has transitioned from a background planning tool or an industry buzzword into an active, real-time operational co-pilot that is integral to the moment-to-moment functioning of the modern warehouse. In this advanced capacity, AI-driven orchestration platforms are making autonomous, millisecond-level decisions to optimize the intricate flow of goods and resources. These systems are responsible for allocating tasks, or “missions,” to both human associates and autonomous mobile robots based on a dynamic and continuous assessment of live operational variables. This includes evaluating worker availability and physical location, monitoring robot battery levels and maintenance schedules, analyzing real-time pick path congestion to prevent traffic jams, and prioritizing incoming orders based on service-level agreements. This level of intelligent automation transforms the warehouse from a static environment governed by fixed rules into a fluid, self-optimizing ecosystem where AI actively guides both human and robotic performance to achieve maximum efficiency and throughput.

The integration of AI into the core of warehouse management systems has created a symbiotic relationship between data, machine learning, and human insight. The most successful operations are those that treat continuous improvement not as a one-time project but as an embedded, daily cultural rhythm. This involves creating a rapid feedback loop where associates on the floor can use performance data generated by their robotic counterparts to suggest practical workflow and route refinements. Management can then use the orchestration platform to quickly model, test, and implement these suggestions, sometimes within a matter of hours. This collaborative mindset extends beyond the warehouse floor, influencing leadership strategy, fostering more innovative vendor partnerships, and even shaping customer engagement by enabling more accurate delivery promises. This “mindset” of perpetual optimization, powered by accessible data and AI-driven tools, has become a core value and a significant competitive differentiator in the fulfillment industry.

Expanding the Scope of Physical Automation

Automating the Entire Internal Flow

While person-to-goods (P2G) systems revolutionized picking productivity by bringing items directly to stationary workers, the next frontier of automation extends to the entire internal logistics flow, creating a more cohesive and uninterrupted system from receiving to shipping. The rise of Robots-to-Goods (R2G) systems redefines how inventory moves throughout the facility, automating the laborious and time-consuming transport functions that connect different operational areas. Using fleets of autonomous mobile robots (AMRs), R2G systems handle tasks such as executing replenishment runs from bulk storage to forward picking areas, moving completed orders from picking zones to packing stations, and managing the cross-docking flow of goods. By seamlessly integrating R2G transport systems with established P2G picking systems, warehouses can achieve a true end-to-end automated process where goods move continuously without requiring manual transport, leading to significant gains in speed, accuracy, and operational balance.

With the persistent surge in e-commerce returns, reverse logistics is no longer a manual, reactive afterthought but has become an integral and highly automated component of a comprehensive fulfillment strategy. The unpredictable and varied nature of inbound returns makes them an ideal candidate for robotic automation. AMRs are increasingly deployed to transport, sort, and process returned items, but the innovation extends further. Automation is now being applied to the inspection and re-slotting processes, powered by data from the original outbound order. This allows the system to make intelligent decisions about whether an item can be immediately returned to stock, requires refurbishment, or should be liquidated. This proactive and data-driven approach transforms returns management from a costly operational bottleneck into a planned, efficient, and value-recovering part of the overall supply chain, improving inventory accuracy and reducing the financial impact of returns.

The Advent of Robots to Goods

The introduction of pervasive automation is forcing a fundamental re-evaluation of how operational success is measured and how human workers contribute value within the modern warehouse environment. The traditional benchmark of success—raw, static efficiency calculated in picks per hour—is being overtaken by flexibility as the paramount key performance indicator (KPI). In a volatile market characterized by fluctuating order volumes, shifting customer demands, and diverse product mixes, the ability to adapt quickly is far more valuable than static peak performance. This conceptual shift is being formalized with the appearance of new, quantifiable KPIs on management dashboards, such as “time to reconfiguration” or “labor redeployment speed.” This focus on adaptability is driving demand for modular robotics platforms and software that allow for the addition of new workflows or the scaling of operations without requiring a complete re-engineering of the entire system.

As automation technology becomes more sophisticated and capable, the collaboration between people and robots is becoming more intentional and specialized. The strategic focus is now on ensuring that robots complement and augment human work, not merely duplicate it. This is leading to the emergence of entirely new roles within the warehouse. Associates are evolving into “workflow coordinators” who manage fleets of robots and “orchestration supervisors” who oversee system-wide performance via interactive dashboards rather than traditional clipboards and spreadsheets. Consequently, training programs are shifting their focus from teaching rote, procedural tasks to developing analytical and problem-solving skills. Workers are being empowered to interpret performance data, identify systemic inefficiencies, and actively participate in optimizing the automated workflows they oversee, adding a layer of human ingenuity to the raw power of robotic execution.

The Strategic Evolution of Fulfillment Networks

Smarter, Greener Network Design

The underlying strategy for designing and managing fulfillment networks is undergoing a fundamental transformation, driven by a convergence of needs for greater resilience, responsiveness, and corporate responsibility. The traditional model of a single, massive flagship distribution center is steadily giving way to a more agile and decentralized network of smaller, strategically located fulfillment nodes. This multi-node approach allows companies to position inventory closer to end customers, which in turn enables faster and significantly more cost-effective ground shipping, reducing reliance on expensive air freight. The critical technology making this distributed model viable is orchestrated automation. A unified orchestration platform allows the entire network to operate as a single, cohesive system, virtually sharing labor, inventory, and capacity to respond dynamically and intelligently to regional demand shifts and supply chain disruptions.

Efficiency in logistics is no longer solely a conversation about cost savings; it has become an essential component of environmental stewardship. Sustainability has emerged as a primary driver of system design, with companies now actively tracking and managing the carbon impact of their fulfillment operations as a core business metric. The inherent efficiency of automation translates directly to significant environmental benefits. For example, the dramatic reduction in walking distance for workers in an AMR-assisted warehouse corresponds to lower energy consumption for lighting and climate control. Furthermore, orchestration platforms are being further optimized to calculate and favor the most environmentally friendly routing and resource allocation strategies. This includes prioritizing ground shipping over air and optimizing truckloads to reduce empty miles, helping companies meet both increasingly stringent regulatory requirements and growing consumer expectations for greener logistics.

Decentralized Multi Node Networks

The shift toward decentralized networks has been accelerated by the need for greater supply chain resilience in the face of unpredictable disruptions. By distributing inventory across multiple smaller facilities rather than concentrating it in one or two large hubs, companies can mitigate the risk of a single point of failure. If one node is impacted by a natural disaster, labor shortage, or transportation issue, the network’s orchestration platform can automatically reroute orders to other facilities, ensuring business continuity and maintaining customer service levels. This distributed approach also enhances a company’s ability to offer a wider range of delivery options, such as same-day delivery or buy-online-pickup-in-store (BOPIS), by leveraging local fulfillment centers and retail stores as micro-fulfillment nodes within the broader network ecosystem. This strategic decentralization creates a more robust and customer-centric supply chain.

Making a decentralized network function effectively required a sophisticated layer of intelligent orchestration that could manage complexity at scale. Platforms like LocusONE provided the central “brain” that allowed a disparate collection of warehouses to operate as a single, synchronized entity. This system enabled the virtual pooling of resources, where labor capacity and inventory levels were visible and accessible across the entire network. If a fulfillment center in one region experienced an unexpected spike in demand, the orchestration system could intelligently divert new orders to another node with available capacity, all without manual intervention. This ability to dynamically balance workloads and leverage the collective strength of the entire network ensured that companies could adapt to regional market shifts in real time, transforming their fulfillment operations from a rigid cost center into a flexible strategic asset that had become a key competitive advantage.