The recent global disruptions, notably the COVID-19 pandemic, have thrust supply chain risk management into the limelight. Companies are urgently seeking strategies to navigate these risks and ensure the resilience and recovery of their operations. This article delves into a multitude of risk management approaches gathered from various industry perspectives.

Understanding Supply Chain Disruption and Risk Management

The Impact of COVID-19 on Supply Chains

The COVID-19 pandemic served as a stark reminder of the fragility in global supply chains. Businesses were confronted with the domino effect triggered by lockdowns and restrictions implemented around the globe. The supply shock hit industries unevenly, with some experiencing severe production halts, while others scrambled to keep up with a sudden surge in demand. This period compelled organizations to recognize the critical nature of having resilient supply chains to weather such unprecedented disruptions.During the pandemic, the widespread recognition of supply chain management’s critical role became clear as consumer behaviors shifted and e-commerce soared. Traditional brick-and-mortar businesses that relied on just-in-time inventory were suddenly at a disadvantage. As a result, businesses have recalibrated their strategies to bolster their supply chain frameworks, showing a renewed commitment to investing in risk management processes.

Developing a Risk Management Mindset

A forward-looking risk management mindset has become more than a choice; it’s a necessity for modern businesses. Firms are now learning to implement dynamic risk assessments that can weigh the likelihood and impact of possible disruptions. These intricate strategies often involve a balance of quantitative analysis and strategic foresight to manifest robust contingency plans that extend beyond immediate responses to potential supply chain shocks.

Crafting Multiple Contingency Plans

Research and Supplier Geography

As businesses grapple with the intricacies of global supply chains, the importance of in-depth supplier research and logistics cannot be overstated. It’s essential for companies to scrutinize their supply networks, understanding the geographic and political climate risks associated with each node. Building a comprehensive picture of where vulnerabilities lie allows businesses to prioritize which relationships and processes require bolstering or alternative solutions.

Auditing and Diversification

An essential part of risk assessment is the auditing of logistics providers. This means examining their histories, operational redundancies, and capacity to recover from various crisis scenarios. Moreover, an effective diversification strategy can act as an insurance policy against supply chain disruptions. By broadening the supplier base, companies are not just mitigating risks; they are securing a competitive advantage in the increasingly complex global marketplace.

Utilizing the PPRR Model

Prevention and Preparedness Strategies

The PPRR model offers a structured approach to supply chain risk management, starting with the development of preventive measures that can aid in avoiding disruptions. Companies that adopt this model work on identifying potential risks and creating systems designed to either prevent or mitigate their impacts. Preparedness involves training and simulations to build organizational responsiveness should preventive measures fail.

Response and Recovery Plans

When a disruption occurs, a well-structured response is crucial to minimize impact. The response phase of the PPRR model emphasizes the need for a coordinated effort, often necessitating clear channels of communication and predefined action plans. Subsequently, the recovery phase is about learning, adapting, and improving. This includes analyzing the event, restoring operations to their pre-disruption state, and implementing enhancements to prevent similar occurrences.

Enhancing Supply Chain Transparency

Beyond Internal Monitoring

Transparency within supply chains is no longer just a matter of internal efficiency; it’s also about trust and accountability. A transparent supply chain can offer insights into operations for external stakeholders, thus attracting customers keen on ethical consumption and investors interested in sustainable practices. Furthermore, this transparency aids in complying with regulatory standards and bolsters goodwill among stakeholders.

The Role of Transparency in Performance and Compliance

Improved supply chain transparency not only streamlines operations but also can lead to better compliance with labor and environmental standards. As regulations evolve, and consumers become more conscious of social and environmental impacts, transparent practices become crucial. They can help companies preempt issues related to compliance, labor practices, or environmental concerns, well before they erupt into full-blown crises.

The Advantages of Regionalized Sourcing

Cost Savings and Reduced Risks

Regionalized sourcing has emerged as a strategy that, while potentially increasing upfront costs, can provide significant long-term savings. It optimizes the supply chain by aligning sourcing with geographic realities, thereby reducing transport times and logistics complexities. This strategy can also limit the carbon footprint of operations and minimize location-based risks such as tariffs or geopolitical tensions.

The Pandemic Learning Curve

The pandemic served as a vivid illustration of the vulnerabilities inherent in globalized supply chains. Companies faced with supply delays realized the essence of having suppliers closer to their production centers or key markets. Such a shift towards regionalized sourcing has allowed businesses to regain stability faster, responding to supply and demand changes more agilely, thus avoiding some of the more severe disruptions.

Metrics Tracking and Predictive Analytics

Key Freight Metrics

Freight metrics provide critical insights into the health and efficiency of supply chains. Monitoring indicators such as loading times, transit durations, maintenance scheduling, and delivery routes is essential for businesses that look to optimize logistic operations. This data-driven approach enables companies to evaluate and choose freight carriers best suited to their needs, improving reliability and cost-effectiveness.

Risk Scenario Simulation

The sophistication of data science and predictive analytics has reached a stage where supply chain managers can not only react to risks but also anticipate them. Simulating diverse risk scenarios equips businesses with the knowledge to create an infrastructure resilient to fluctuations in demand, inventory levels, and transit delays. This foresight is invaluable in creating a competitive edge and ensuring customer satisfaction.

Cybersecurity in the Supply Chain

Identifying Cyber Vulnerabilities

Cyber vulnerabilities represent a growing threat within supply chains. As chains become more digitalized, they are increasingly susceptible to cyberattacks that can disrupt operations and lead to data breaches. Companies need to conduct regular vulnerability assessments and enforce security protocols to guard against such threats. Establishing stringent cybersecurity standards for all facets of the supply chain is imperative to shield sensitive information and integral systems.

Third-Party Involvement and Employee Education

Managing third-party risks is crucial, as the supply chain extends beyond the confines of a single company. Ensuring that partners uphold the same cybersecurity standards is essential for creating a secure supply network. In addition, ongoing employee education programs are critical. These programs should focus on teaching staff about potential cyber threats and the actions they should take to prevent breaches.

Supply Chain Visibility and Real-Time Monitoring

Gaining Comprehensive Visibility

Full visibility into the supply chain is indispensable for managing risks effectively. Understanding every link—from sourcing raw materials to delivering the final product—enables a company to identify potential problem areas before they escalate. This heightened awareness fosters robust relationships with suppliers and customers, as it allows for transparent communication and builds trust.

Leveraging Technology for Continuous Monitoring

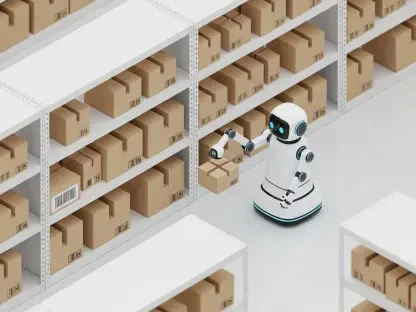

Advancements in AI and analytics have revolutionized the ability of companies to monitor their supply chains continuously. These technologies facilitate the detection of emerging risks, providing real-time insights that allow for prompt responses. By automating various monitoring tasks, technology not only hardens security but also frees human resources to focus on critical decision-making and relationship building.

The Critical Role of Multi-Sourcing

Diversifying Supplier Bases

The practice of multi-sourcing is increasingly recognized as vital in the realm of supply chain risk management. By distributing the sourcing of products or raw materials across multiple providers, a business can substantially diminish the impact of any single supplier’s disruption. This approach instills resilience within the supply chain, ensuring a steady flow of materials despite individual supplier challenges.

Building Relationships and Clear Communication

Successful multi-sourcing is contingent upon developing and maintaining strong relationships with a diverse group of suppliers. It necessitates transparent and consistent communication to align expectations and streamline coordination efforts. By fostering these relationships and implementing clear communication protocols, businesses can enhance their flexibility and responsiveness in the event of unexpected supply chain disturbances.