With decades of experience spanning the supply chain and delivery sectors, Rohit Laila has been at the forefront of the logistics industry’s technological evolution. His passion for innovation provides a unique lens through which to view the recent strategic acquisition of Stellium by the international technology group Körber. This merger signals a significant shift in the SAP supply chain consulting landscape, promising to blend deep regional expertise with a powerful global footprint. We sat down with Rohit to explore the implications of this partnership, discussing how the combined entity, Körber Stellium, plans to leverage new technologies like AI and integrated business planning to forge the resilient, intelligent supply chains of the future. The conversation delves into the practicalities of integrating corporate cultures and the strategic shifts companies must embrace to thrive in an increasingly complex world.

This acquisition combines Stellium’s strong presence in North America and the Middle East with Körber’s established footprint. How will this new global reach specifically benefit customers, and what are the first steps to integrating these distinct regional teams to ensure a seamless client experience?

This is truly a case where the whole is greater than the sum of its parts. For our customers, especially those with global operations, this means they no longer have to patch together different consulting partners in different regions. They now have a single, premier global firm for their end-to-end SAP Supply Chain Management needs. The immediate benefit is consistency and a depth of expertise that is now globally accessible. Our first step is all about people and process alignment. We are creating integrated teams that blend the deep local market knowledge from the Stellium side with Körber’s established global frameworks. This ensures that a client in Houston receives the same high-caliber, forward-thinking service as a client in Europe or India, right from day one.

You’ve highlighted new offerings like SAP Digital Manufacturing and Integrated Business Planning. Could you share a practical example of how these tools, combined with AI and automation, will help a client build a more resilient and intelligent supply chain in today’s complex market?

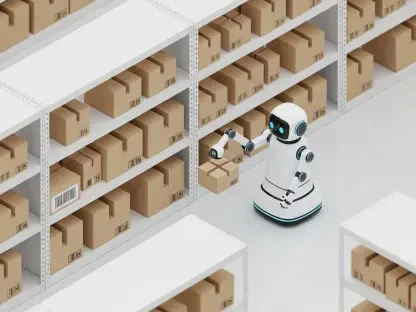

Absolutely. Imagine a manufacturer dealing with sudden, unpredictable shifts in consumer demand and material availability. In the past, this would cause chaos. Today, using SAP Integrated Business Planning, they can use AI-driven models to forecast these shifts with much greater accuracy. This data then flows directly into SAP Digital Manufacturing, which can automatically adjust production schedules and re-route materials on the factory floor. This isn’t just about efficiency; it’s about building a supply chain that can sense, think, and respond. It transforms the operation from a rigid, brittle system into a living, resilient organism that can absorb shocks and adapt, which is the very definition of a future-ready supply chain.

With Stellium’s leadership team continuing to manage operations at Körber Stellium, what specific measures are being put in place to blend the two corporate cultures? Can you walk us through how you will foster collaboration between the incoming team and Körber’s global leadership?

Cultural integration is paramount, and we’re approaching it with great care. It’s not a takeover; it’s a partnership. By keeping the Stellium leadership team in place, we preserve the very spirit and domain expertise that made them so successful. The key is fostering a shared mission. We are establishing joint steering committees and cross-functional project teams where experts from both legacy organizations work side-by-side with Körber’s Competence Center Consulting global leadership. This isn’t about issuing top-down directives; it’s about collaborative problem-solving and creating a unified vision where innovation is the common language. It’s how we ensure the new Körber Stellium has a culture that is both entrepreneurial and globally scaled.

The stated goal is to help customers master the challenges and opportunities of tomorrow’s supply chains. Beyond specific software, what are the key operational or strategic shifts you believe companies must make to compete, adapt, and win over the next decade?

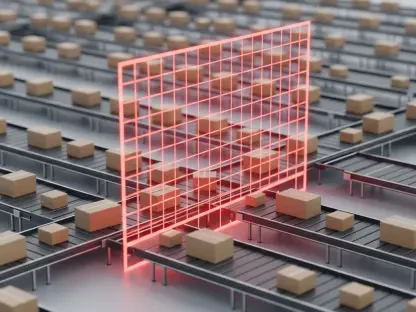

Technology is the enabler, but the real transformation is a shift in mindset. For decades, many viewed the supply chain as a cost center to be optimized. To win in the next decade, companies must see it as their primary competitive advantage. This means breaking down internal silos and embracing data-driven decision-making from the C-suite to the warehouse floor. It requires a move from being reactive to being predictive, using tools like AI and advanced analytics to anticipate disruptions before they happen. Companies must build agility into their core strategy, understanding that the ability to adapt quickly is more valuable than static efficiency. That’s the strategic leap from just surviving to truly thriving in this complex new world.

What is your forecast for the evolution of supply chain management over the next five years?

I believe we are on the cusp of a profound transformation where supply chains become fully autonomous and predictive ecosystems. The conversation will move beyond just visibility to genuine intelligence, where AI and automation are not just tools but the central nervous system of the entire operation. We will see self-correcting supply chains that can automatically re-route shipments, adjust inventory levels, and even re-tool manufacturing lines in response to real-time data without human intervention. The focus will be less on managing individual functions and more on orchestrating a complex, interconnected network that delivers not just products, but a resilient and adaptive competitive edge. This is the future we are building toward.