The journey of fresh produce from farm to shelf is a race against time, where a single delay can translate into significant spoilage and financial loss across an entire supply chain. The implementation of robotic automation represents a significant advancement in the fresh food logistics sector. This review will explore the evolution of this technology, its key features, performance metrics, and the impact it has had on high-volume grocery distribution, using Cimcorp’s system at the REWE fulfillment center as a case study. The purpose of this review is to provide a thorough understanding of the technology, its current capabilities, and its potential for future development in solving the unique challenges of perishable goods handling.

The Rise of Automation in Perishable Logistics

In the demanding world of fresh grocery distribution, the margin for error is razor-thin. Perishable goods necessitate a supply chain built on speed, unwavering reliability, and absolute precision to maintain quality and minimize waste. Recognizing this, major retailers like REWE are moving beyond traditional manual processes and embracing comprehensive automated systems to manage the complexities of their high-velocity logistics.

This strategic shift toward automation is not merely an operational upgrade; it is a fundamental response to the pressures of modern commerce. As consumer expectations for freshness and availability continue to rise, the ability to accurately and efficiently move temperature-sensitive products becomes a key competitive differentiator. In this context, robotic fulfillment is a critical enabler of a more resilient and responsive supply chain.

Anatomy of a Modern Automated Fulfillment System

The Integrated Warehouse Control System

At the core of this sophisticated operation is Cimcorp’s Warehouse Control System (WCS), the software that orchestrates every movement within the facility. This centralized platform acts as the operational brain, seamlessly integrating all logistical stages. From the moment goods arrive and their barcodes are scanned, the WCS takes command, directing depalletizing, managing real-time inventory levels, and assigning picking tasks to the robotic fleet.

Its true value lies in providing REWE with absolute control and transparency over its entire material flow. By processing vast amounts of data in real time, the WCS optimizes every decision, ensuring that outbound orders are assembled with pinpoint accuracy and dispatched according to precise delivery schedules. This level of digital oversight is instrumental in guaranteeing seamless execution and operational efficiency.

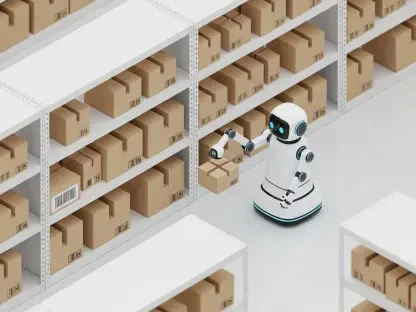

Robotic Order Picking and Handling Technology

The physical workhorse of the fulfillment center is a fleet of automated gantry robots designed for high-speed order picking. These machines handle an impressive volume of approximately 29,000 units daily, navigating the warehouse to retrieve and sort crates with an efficiency that far surpasses manual capabilities. The system is engineered to meticulously follow both FIFO (First In, First Out) and FEFO (First Expired, First Out) principles, a critical function for ensuring that products with the nearest expiration dates are shipped first, thus maximizing freshness on store shelves.

To safeguard against operational interruptions, the system incorporates built-in redundancy through dual robot cells. This design ensures that if one unit requires maintenance, another can immediately take over its tasks, allowing the fulfillment center to maintain continuous, uninterrupted operation. This guarantee of uptime is essential in an industry where delays directly impact product viability and profitability.

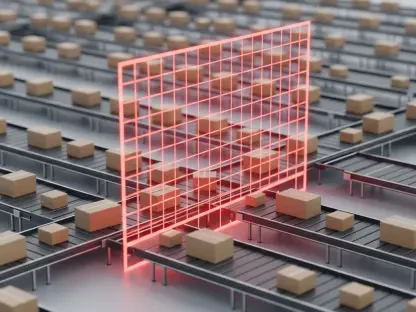

Comprehensive Traceability and Quality Assurance

A defining feature of the automated system is its capacity for complete end-to-end traceability. Every crate of produce is meticulously tracked from its entry into the facility until it is loaded onto a truck for delivery. This unbroken chain of custody is logged within the WCS, creating a detailed digital record of each item’s journey through the distribution process.

This granular level of tracking provides far more than just operational insight; it is a cornerstone of modern food safety and quality assurance. In the event of a product recall, the system enables rapid identification and isolation of affected batches, minimizing risk to consumers. Furthermore, this data supports rigorous quality control, ensuring that only the freshest products reach the customer.

Evolving Trends in Automated Warehouse Management

One of the most significant trends emerging from the adoption of advanced automation is its positive influence on the workplace environment and employee wellbeing. Contrary to concerns about technology displacing workers, the experience at REWE demonstrates a symbiotic relationship where automation enhances human roles. The system has reportedly generated excitement among the staff and transformed the nature of their work.

This shift has profound implications for business performance. By automating strenuous and repetitive tasks, the system alleviates common operational pain points, such as the persistent struggle to fill overtime hours for undesirable shifts. This results in a more engaged and satisfied workforce, which in turn contributes to greater overall productivity and a more positive company culture.

Real World Impact: The REWE Oranienburg Case Study

The REWE fresh food fulfillment center in Oranienburg, Germany, serves as a powerful testament to the real-world impact of this technology. This large-scale operation is responsible for supplying a vast network of over 370 supermarkets and 580 shops throughout the greater Berlin area. The sheer volume and geographic spread of this network underscore the critical need for a logistics system that is both robust and flawlessly reliable.

For REWE, the implementation of Cimcorp’s system has been transformative. In the fresh food sector, a missed delivery window is not just an inconvenience; it represents a direct and significant financial loss due to spoilage. By ensuring precise, on-time deliveries, the automated system directly prevents these losses. This operational certainty translates into better-stocked shelves, higher-quality produce for consumers, and an improved overall customer experience in stores.

Overcoming Challenges in Fresh Food Distribution

The grocery sector is fraught with inherent challenges that robotic fulfillment is uniquely positioned to address. Technically, the system is engineered to manage a high-velocity inventory of perishable goods, a task that requires a delicate balance of speed and careful handling. The automation directly mitigates market-driven obstacles, most notably the persistent labor shortages that have strained supply chains globally.

Financially, the technology tackles the dual risks of product spoilage and order inaccuracies, two of the largest sources of revenue loss in the industry. With its end-to-end control, meticulous inventory management, and built-in redundancies, Cimcorp’s system provides a comprehensive solution that strengthens operational resilience against these persistent limitations, creating a more stable and predictable distribution model.

Future Outlook for Robotic Grocery Logistics

The trajectory for robotic fulfillment in the grocery sector points toward even greater sophistication and integration. Future developments are expected to include a deeper fusion with artificial intelligence for advanced predictive analytics. This will enable systems to not only manage current inventory but also to forecast demand with greater accuracy, further optimizing stock levels and reducing waste.

Moreover, the technology will likely evolve to include more advanced robots capable of handling an even wider array of delicate produce with human-like dexterity. As these systems become more adaptable and cost-effective, their adoption is projected to expand across the industry, moving from large-scale fulfillment centers to smaller, regional distribution hubs, ultimately creating a more agile and sustainable fresh food supply chain.

Conclusion: A New Standard in Fulfillment

The collaboration between Cimcorp and REWE provided a clear demonstration of automation’s capacity to redefine the standards of fresh food logistics. The review of the Oranienburg facility revealed a system that successfully merged software intelligence with robotic precision to solve longstanding industry challenges. By delivering unparalleled reliability, the technology boosted operational efficiency and significantly reduced the financial risks associated with perishable goods.

Ultimately, the implementation achieved more than just logistical optimization; it created a positive ripple effect that improved employee satisfaction and enhanced the end-customer experience. The project set a new benchmark for what is possible in high-volume grocery distribution, establishing a robust model for a more efficient, traceable, and resilient food supply chain.